KTH Royal Institute of Technology

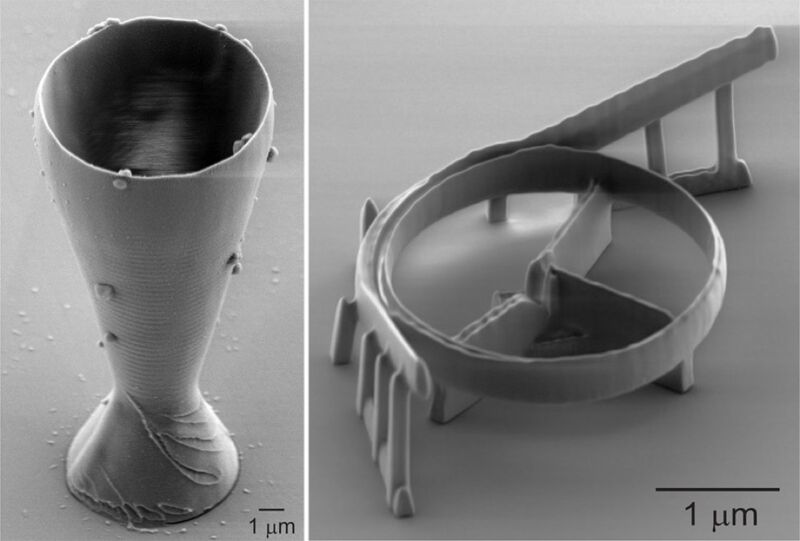

A team from Sweden has developed an innovative 3D printing technique for silica that streamlines the energy-intensive and complex process. As a proof of concept, they 3D-printed the world’s smallest wineglass (made of actual glass) with a rim smaller than the width of one human hair, as well as an optical resonator for fiber optic telecommunications systems—one of several potential applications for 3D-printed silica glass components. The researchers described their method in a paper published in Nature Communications.

“The backbone of the Internet is based on optical fibers made of glass,” said co-author Kristinn Gylfason of the KTH Royal Institute of Technology in Stockholm. Our 3D printing technique allows us to print all the filters and couplings that are needed in these systems. This opens many new possibilities.”

The authors state that silica (amorphous silicon oxide) is proving to be a difficult material for 3D printing. This is especially true at the nanoscale. However, several methods have been developed to help overcome this problem, including stereolithography. Direct ink writing and digital light processing. Except for one study in 2021 that reported nanoscale accuracy, even those methods were only able to produce feature sizes around a few tens of millimeters.

All of these processes use silica-nanoparticles in different organic mixtures. So, the printed structures will be composites made of organic materials. They lack the desirable properties of silica glasses (i.e. chemical and thermal stability, hardness and optical transparency across a wide spectrum of wavelengths). It requires an extra sintering step at high temperatures of around 1,200° Celsius (2,192° F) for several hours to remove the organic residues and achieve those properties. This energy-intensive step limits the potential applications, as only substrate materials that are able to withstand high temperatures can be utilized. Some approaches require 3D printed structures to be assembled into a finished form. This is difficult at the micrometer level.

Gylfason created a 3D printing technique that uses silica to print glass. et all. The researchers turned to hydrogen-silsesquioxane. This inorganic material is similar to silicon and can be pattern by electron beams or ion beams. It also responds to certain wavelengths of UV radiation. Their method has a major advantage in that it does not use organic compounds as photoinitiators and binders, which remain on the substrate as is done with stereolithography and direct ink writing. Their method relies instead on the direct cross-linking with the inorganic HSS.

The process consists of three steps. The first step is to drop-cast HSQ that has been dissolved in organic solvants onto a surface. After the HSQ dries they trace the 3D shape with a laser beam focused at sub-picoseconds. The HSQ that has not been exposed is then dissolved using a potassium hydroxide. Raman spectroscopy revealed all the features of silica in the printed microstructures.

But there were also traces remaining hydrogen and carbon. For applications requiring a more pure silica glass, the residual organics can be removed by annealing the structures at 900° Celsius (1,652° F)—an extra step, granted, but at a much lower temperature than the usual extra sintering step. The spectrum of the structures then matched a commercially available fused silica substrate. The authors found that while annealing 3D printed microstructures could cause them to shrink, they did not distort. Instead, their silica structures shrank by around 6%, as opposed to 16-56% for objects created using stereolithography or direct ink writing.

The authors also printed a small version of the KTH Logo, a cantilever and a spiral conical, along with a tip made from silica optical fiber. The authors believe their method can be used to create customized lenses for micro-robots and medical devices. Coating 3D printed microstructures in nanodiamonds (or ferrous nanoparticles) could allow for further customization of properties, such as hybrid quantum photonics incorporation or magnetically removing motion control.

“The concerns when integrating 3D printing methods are usually different for different applications,” said co-author Po-Han Huang, a graduate student at KTH. “Even though optimization of our method is still required for different applications, we believe our method presents an important and necessary breakthrough for 3D glass printing to be used in practical scenarios.”

Nature Communications, 2023. 10.1038/s41467-023-38996-3 (About DOIs).