Among the many industrial sectors at the moment reaping the advantages of additive manufacturing is the maritime trade. Excessive requirements, excessive floor high quality, consideration to element, sturdy supplies and customised design are simply a few of the sector’s necessities that 3D printing can meet, performing as a viable and generally obligatory different to conventional manufacturing strategies. Why and the way can 3D printing be utilized to the maritime sector? To search out out extra, we spoke with Superfici, an Italian firm that is likely one of the first to put in totally 3D printed components on board ships. Paolo Nazzaro, CEO and co-founder, answered our questions.

3DN: May you introduce your self?

Whats up, my title is Paolo Nazzaro and I’m one of many founding companions of Superfici, together with Davide Telleschi and Guido Zannoni. I’m a nautical designer with a PhD in nautical and sustainable product design. Since 2015, I’ve been an adjunct professor on the Nautical and Marine Design diploma on the College of Genoa. My reference to 3D printing was born in 2010 from an expertise I had throughout an internship with an organization that develops diving gear. On this event, I had the chance to create a number of prototypes with one of many first skilled 3D printers put in within the firm.

The founders of Superfici

3DN: What’s Superfici’s mission?

Superfici was born in 2016 in Liguria, from the thought of introducing additive manufacturing to the shipbuilding sector. The problem is to convey innovation to a world notoriously linked to conventional, artisanal manufacturing. Superfici responds to the excessive demand for the manufacturing of extremely detailed fashions on this sector. This led to an in-depth examine of supplies and floor therapy. The event of this course of has supplied the required know-how to have the ability to provide in the present day numerous elements which can be put in instantly on board boats of assorted sizes. Right this moment, Superfici is a whole specialist in 3D companies for the maritime trade.

3DN: Why did you go for additive manufacturing?

The naval sector is a world of small portions, however with a excessive diploma of customization and stylistic evolution. The fixed seek for new constructive proposals and complicated shapes makes it a fertile sector for the introduction of additive manufacturing. The pattern amongst shipyards is to distinguish themselves from their rivals by providing distinctive options, which are sometimes hampered by the issue of development and the excessive value of manufacturing elements. 3D printing is due to this fact turning into a viable possibility, whereas having to deal with the excessive floor high quality required.

3DN: What 3D printing processes and supplies does Superfici use?

We primarily use fused deposition modeling (FDM) and resin 3D printing. Superfici at the moment has a fleet of 15 3D printers of assorted sizes. So far as supplies are involved, we have now an settlement with a producer in northern Italy who produces thermopolymers underneath our personal model title. The supplies we primarily use are ABS, ASA and PETG. Our direct relationship with the producer permits us to ensure a really excessive degree of high quality.

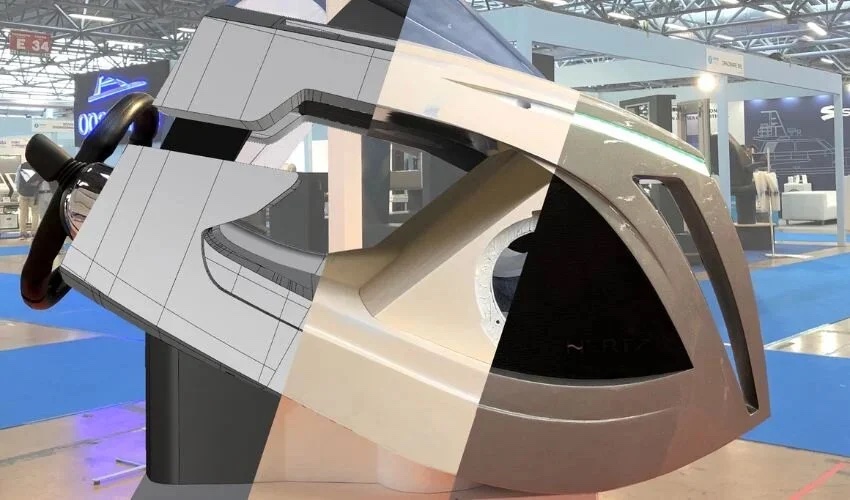

The primary management cabin for a 30m Amer 94′ motor yacht, totally 3D printed by Superfici in 2018

3DN: How do you see 3D printing evolving within the maritime sector?

3D printing can meet the varied wants of development websites and designers. The pattern is in the direction of the manufacturing of bigger and bigger articulated components. One other risk is to provide molds for boat constructing. Right this moment, the big variety of out of date molds poses an actual downside of disposal and storage. The opportunity of creating them by additive manufacturing with thermoplastic supplies may convey many advantages to the trade.

3DN: What are Superfici’s most excellent initiatives?

We’ve accomplished quite a lot of initiatives over time, together with the primary 3D-printed dashboard mounted on a yacht on the San Remo Amer shipyard. There’s additionally the event of a dashboard for SACS inflatable boats, totally designed to make the most of the total potential of additive manufacturing. Lastly, we current the primary 3D-printed steering wheel with a multi-functional show built-in into the middle, created utilizing generative design.

A 3D-printed steering wheel

We’re additionally engaged on a number of fronts to convey new concepts to shipyards, and to proceed introducing additive manufacturing into manufacturing. So there’s no scarcity of initiatives. Superfici is consistently evolving, and analysis and growth are on the coronary heart of the way in which we function.

3DN: Any final phrases for our readers?

The primary challenges stem from the range of the requests we obtain, and the truth that the ever-increasing measurement of the components implies a demanding manufacturing strategy. As well as, our merchandise have to resist the exterior stresses of the marine setting, resembling excessive temperatures, salt water and impression. The boat object itself is a fancy physique that strikes and twists in numerous instructions. All this requires a substantial amount of preliminary examine and compliance with strict requirements, that are important on this work. Yow will discover extra data on the Superfici web site HERE.

What do you consider Superfici? Is AM rising in prominence within the maritime trade? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly publication right here, the most recent 3D printing information straight to your inbox! You may also discover all our movies on our YouTube channel.

*Cowl Photograph Credit: Superfici