Stanford’s newest breakthrough in 3D printing expertise allows the manufacturing of 1 million dust-sized particles per day. Whereas 3D printing has gained widespread adoption on a macroscale stage, this development paves the best way for microscale 3D printing to grow to be extra commonplace.

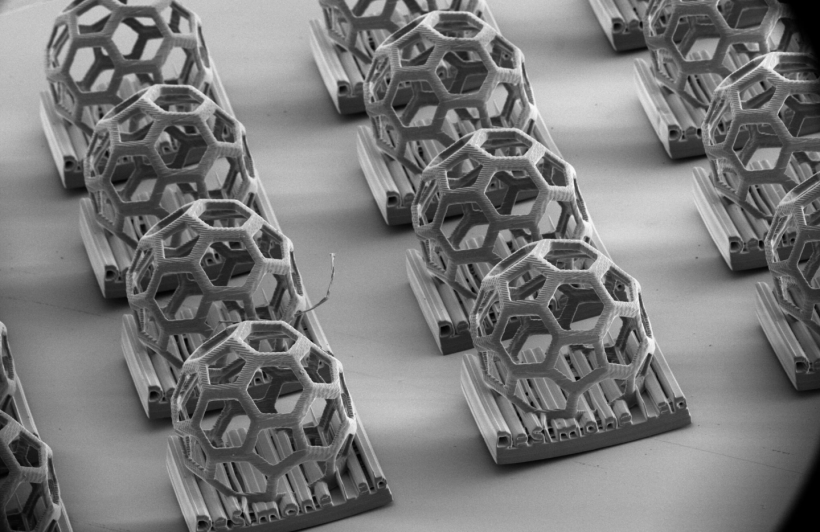

(Picture : DeSimone Analysis Group, SEM courtesy of Stanford Nano Shared Amenities)

The 3D-printed DeSimone lab brand, that includes a buckyball geometry, demonstrates the r2rCLIP system’s capacity to provide advanced, non-moldable shapes with micron-scale options.

Unveiling New 3D Printing Approach

Researchers from Stanford College have unveiled a groundbreaking approach in 3D printing, enabling the manufacturing of as much as a million microscale particles every day.

These minute particles, resembling mud particles to the bare eye, boast intricate detailing and provide versatility for varied purposes, together with microfluidics, vaccine supply, and microelectronics, as per a current press launch.

Whereas 3D printing, or additive manufacturing, has flourished in producing client items like sneakers, listening to aids, and home items on a macroscale stage, this innovation opens doorways to microscale manufacturing.

Historically, attaining high-resolution output at microscopic scales necessitated compromising manufacturing velocity, however this new methodology addresses this limitation.

Underneath the management of Joseph DeSimone, a professor of Translational Drugs at Stanford College, a analysis group has been pioneering a scalable methodology for microscale 3D printing generally known as steady liquid interface manufacturing (CLIP).

Their newest breakthrough entails the institution of an industrial-scale mannequin for 3D printing microparticles, signaling a big development in microscale manufacturing.

Using UV Gentle

CLIP makes use of UV gentle to swiftly solidify resin into desired varieties. Thisinvolves an oxygen-permeable window positioned above the UV gentle projector, serving as a “dead-zone” to forestall resin from adhering to the window whereas enabling exact options to be solidified onto the particle.

Of their current analysis endeavors, the group has established a roll-to-roll setup to facilitate the mass manufacturing of intricately formed particles considerably smaller than a human hair. This setup entails a meticulously tensioned movie being fed into the CLIP printer, the place customizable shapes are printed.

Subsequently, the movie undergoes varied processes, together with washing, solidification, and extraction of the shapes on an meeting line.

Termed roll-to-roll CLIP (r2rCLIP), this revolutionary methodology permits the emptied movie to be rolled again up after the completion of the manufacturing course of.

Additionally Learn: Chameleon Impressed 3D-printing Ink Adjustments Colours in a Single Print Job

In distinction to the normal methodology, which requires the painstaking and time-consuming particular person removing of printed particle batches, r2rCLIP boasts the aptitude to provide 1,000,000 particles every day.

Joseph DeSimone, head of the lab, emphasised the importance of their give attention to translational manufacturing science. He acknowledged within the press launch their laboratory is devoted to growing instruments that facilitate scalability. This achievement exemplifies the impression of that focus.

Representing a big development in 3D printing, the event of r2rCLIP is poised to revolutionize varied industries.

Joseph DeSimone, the lead researcher, famous that this innovation marks a transition from solely specializing in the printing course of to exploring the huge potential purposes of 3D merchandise themselves.

He emphasised that whereas r2rCLIP lays the inspiration for transformative expertise, the following part entails figuring out high-value purposes for this groundbreaking method.

Associated Article: China-US Scientists Unveil World’s Strongest 3D-Printed Titanium Alloy

ⓒ 2024 TECHTIMES.com All rights reserved. Don’t reproduce with out permission.