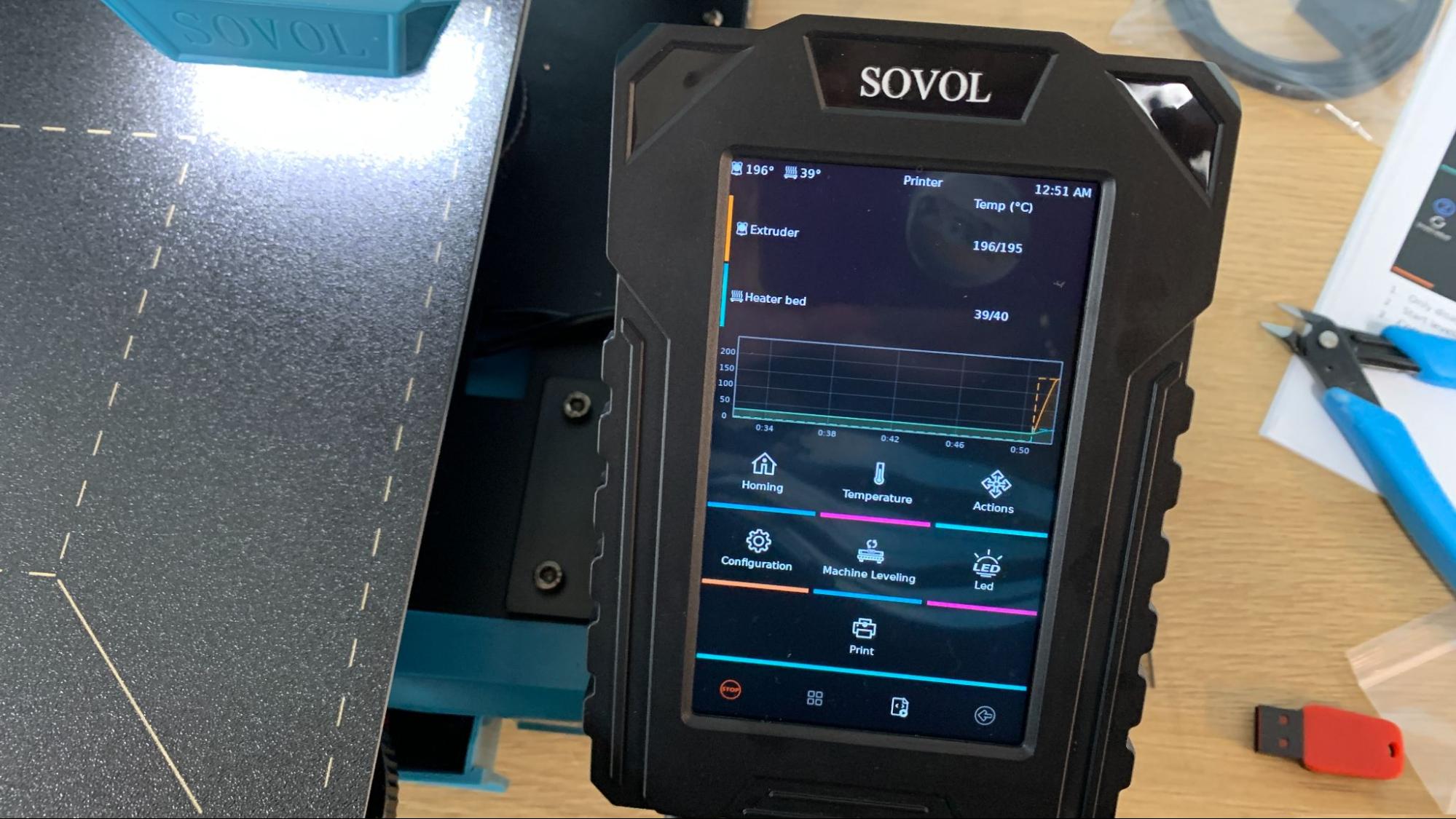

The Sovol SV07 makes Klipper affordable and accessible to everyone with its easy-to-use bed slinger. In 2023, several companies have rushed to add Klipper versions to their 3D-printers. This fast and accurate software was only available by installing it on your Raspberry Pi attached to your printer until last year. Klipper is made easy by Sovol, who has it mounted on a 5-inch touch screen on the printer.

The SV07, which retails for $339, looks like an old-fashioned Cartesian printer. SV01 Pro We reviewed last year. KlipperScreen is an easy-to-navigate display that displays thumbnails and details about your print. It comes with all the features that we look for in a 3D Printer: automatic bed leveling and PEI coated flex plates. Direct drive with a metal hotend. The SV07 comes with a curtain-fan attached to its X gantry for increased cooling.

The SV07 can hit print speeds up to 500 mm/s, and comes with input shaping tuned from the factory that’s pretty decent. If you’d like to fine-tune the calibration, an accelerometer comes included. The SV07 makes Klipper so easy, it’s one of the Best 3D Printers we’ve seen of this new category.

Sovol SV07 Specifications

| Build Volume | 220 x 220 x 250 mm (8.6 x 8.6 x 9.8 inches) |

| Material | PLA/PETG/TPU |

| Extruder Type | Direct Drive |

| Nozzle | Creality K1 |

| Build Platform | Heated PEI spring steel sheet with textured surface |

| Bed Leveling | Automatic with sensor |

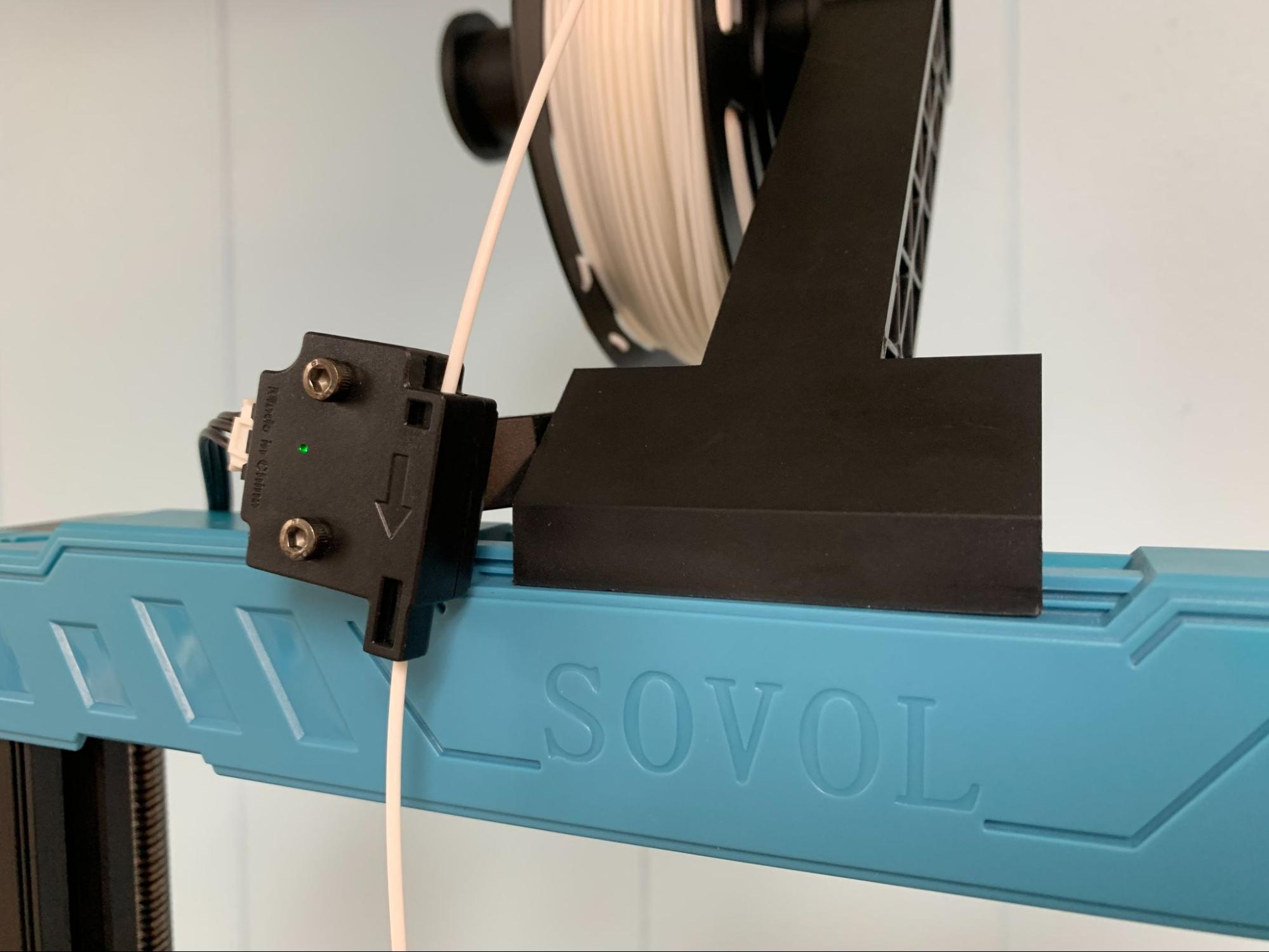

| Filament Runout Detector | Yes, |

| Connectivity | USB Drive Type C with Ethernet and WiFi |

| The interface | LED touch screen fluidd |

| Machine Footprint | 460 x 457 x 625mm (18.1 x 17.9 x 24.6 inches) |

| Machine Weight | 9.7 kg (21.3 lbs). |

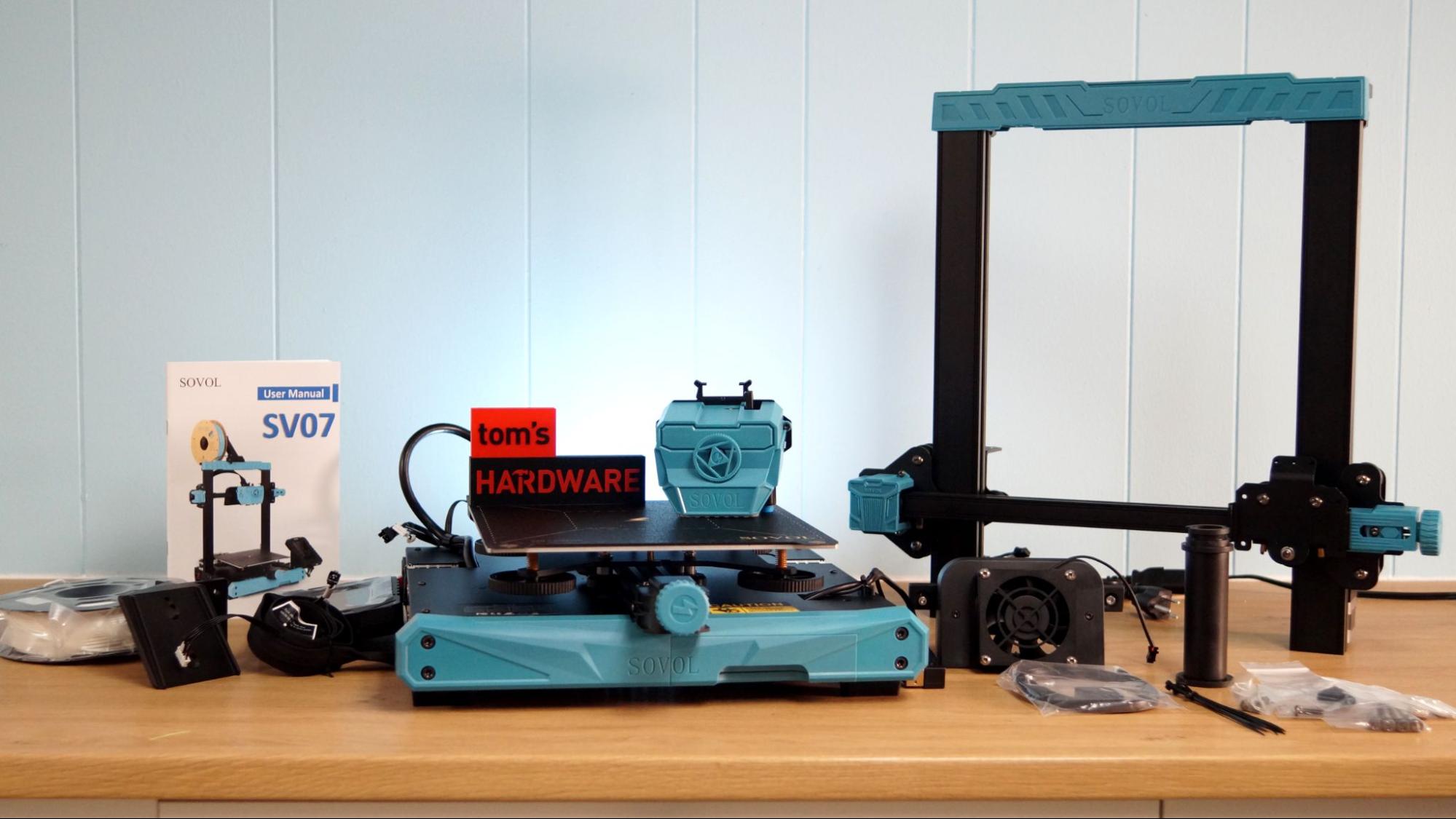

Sovol SV07 in the box

You get everything you need for your printer setup with the Sovol SV07. The Sovol SV07 comes with everything you need to set up your printer. You also get tools for building and maintaining the printer. There’s also a small spool of white PLA to print your first model.

The USB stick includes test models that can be printed, as well as a pdf version of the manual. There’s also a detailed paper copy of the manual.

Sovol SV07: Design and construction

First, the SV07 is not an upgrade from or sequel to the SV06 – these are two entirely different machines. The SV07 is a machine that feels similar to an Ender style The machine is the The SV06 is a i3 style (cough, Prusa, cough).

The SV07 has more injected molded parts than its brethren, all in a stylish Robin’s Egg blue. Some parts are purely decorative, such as the front case, which hides a drawer for tools, or the large extruder lid, which houses an impressive number of LED lights. Some parts are functional, such as the top gantry and adjustment knobs.

I was relieved to see that Sovol didn’t repeat the missteps of BIQU’s Hurakan Klipper came preinstalled but was not explained. Sovol chose to install Klipper on an easy to use pad, which has a graphic interface that’s much easier to navigate and gives you more control options than the average 3D printer. Most importantly, there’s no exposed SD cards containing critical config files you can accidentally remove. All of the data is securely tucked away in the pad.

I would also like to point out that Sovol has made the right decision and partnered with Klipper in order to run the open-source Klipper firmware. You have full access to Klipper and the ability to tweak the config file and add mods to your heart’s content.

Klipper Pad has all ports and plugs, unlike other 3D printer displays. The pad is powered by one plug, while the other carries data. There are two ports for USB – one on the bottom, another on the side – which can accommodate a web camera or a USB stick for manually adding files. There’s also a USB-C port and a plugin for the accelerometer for fine-tuning input shaping.

It has all of the features that I want in a Cartesian Machine: Dual Z-axis, Direct Drive, Metal PEI Flex Sheet, and an All-Metal Hotend. This combination of components promises clog-free printing and effortless printing.

It has a Volcano-style hotend with a grippy, planetary-geared nozzle that provides a faster flow and plenty of control. It uses the same Creality nozzle designed for the K1. Although the nozzles share the same threads as the K1, the Sovol SV07 has an extra length on the tip so that it can peek out beyond the silicone sock.

Unfortunately, the printer is only quiet when it’s not running. While the cooling fan of the printer will stop when it’s completely cooled, the noise from the fan while it’s running is loud. It’s the price we pay for speed. I don’t think the SV07 could print the way it does without that extra cooling, which is aimed at precisely the right spot.

Fluidd, the Fluidd software on your computer, can be used to upload files remotely using the Sovol SV07’s built-in WiFi.

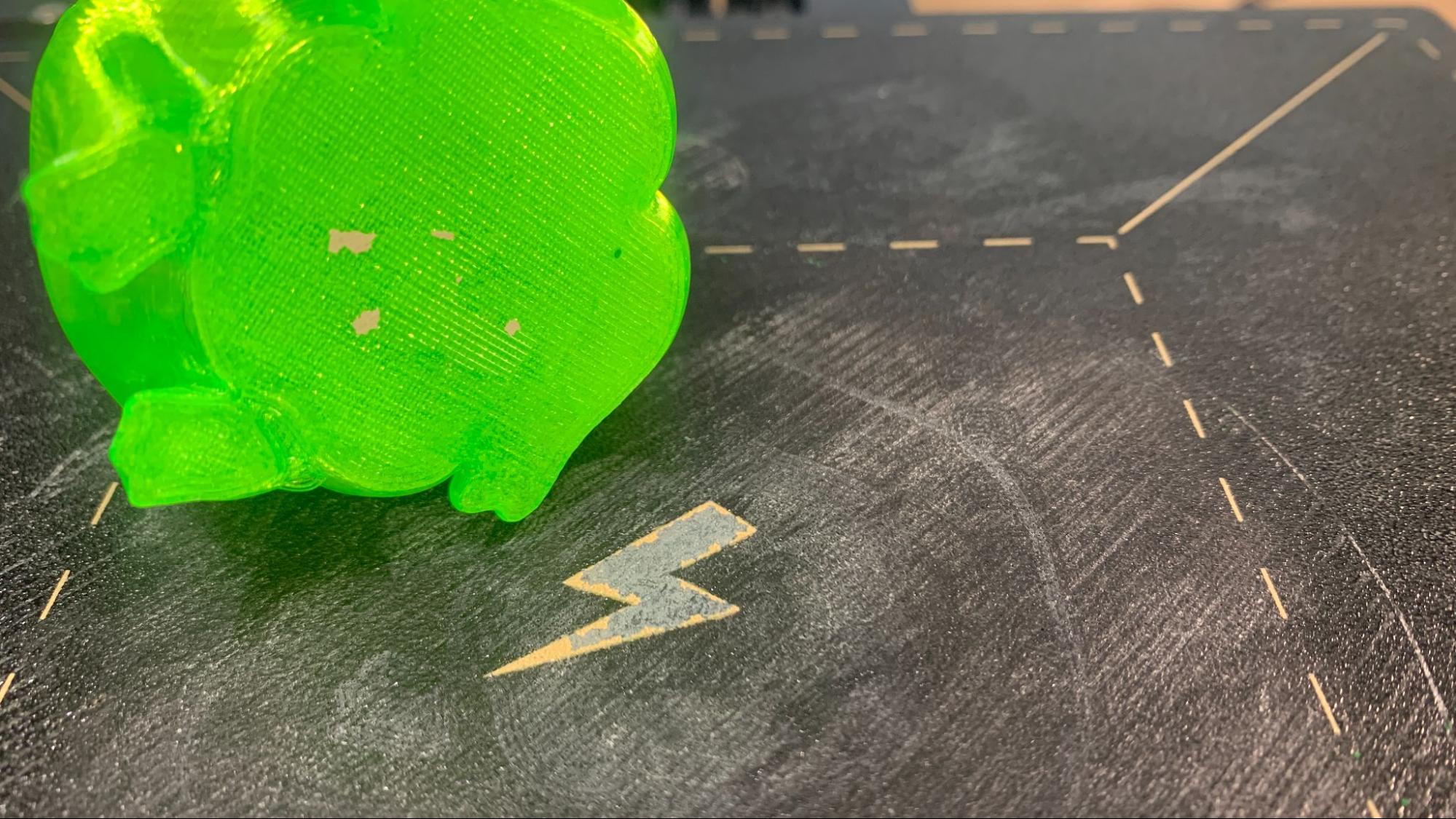

The SV07 comes with a two-sided metal flexplate that is PEI coated and removable. The prints stuck or came off easily. There were painted details on the surface which adhered to my prints.

Assembling Sovol SV07

It took you about 30 minutes to assemble the printer. The instructions are clear.

Four bolts are used to attach the gantry from below. You’ll need to attach the screen holder, tool head and curtain fan with screws. The spool and screen simply pop into position. Wiring is the last step and it is easy to understand and label everything.

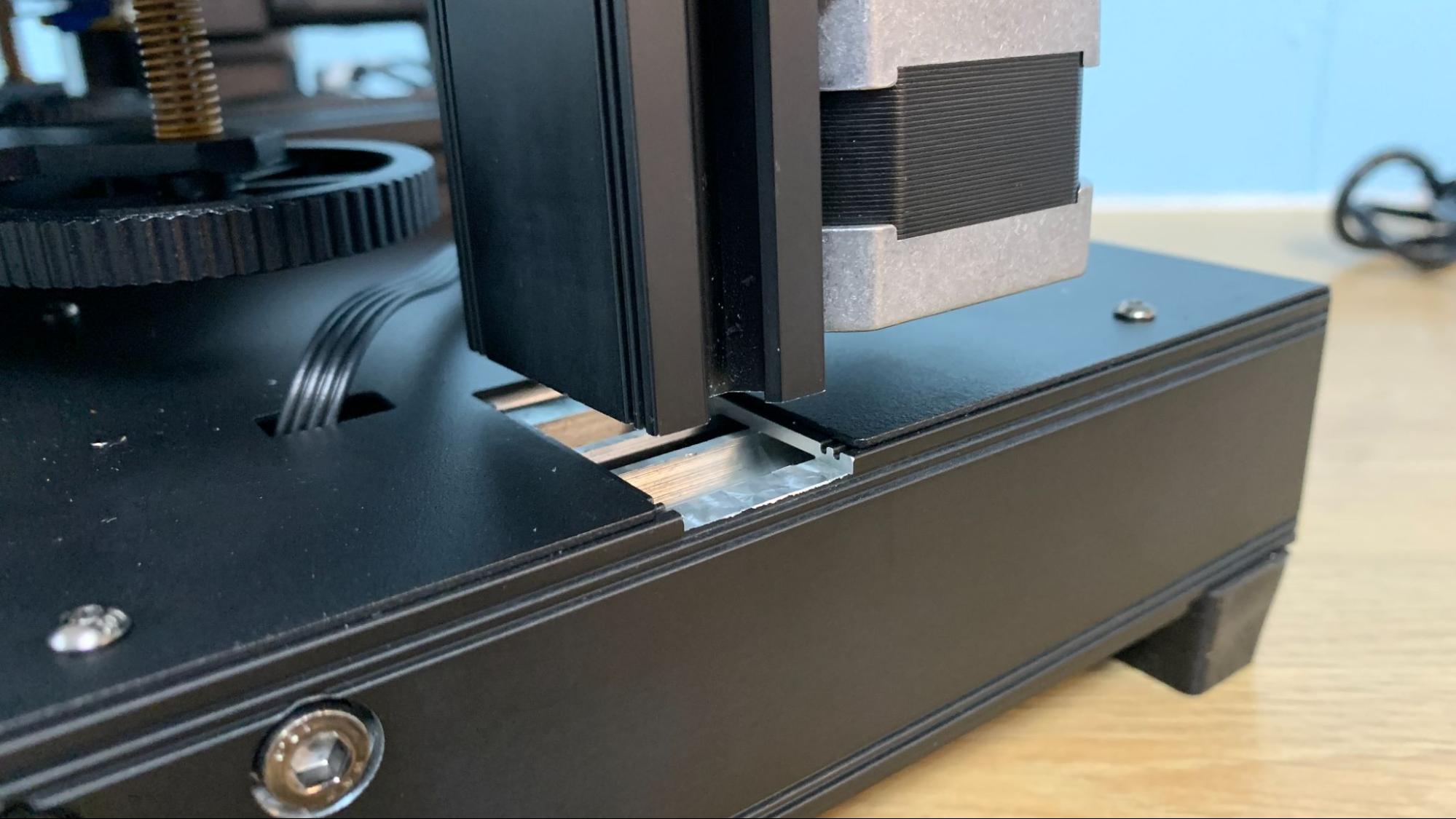

Check that the eccentric nuts on the toolhead and under the bed are not wobbly. Then finally check the voltage switch – I needed to flip it to 115v.

Our test printer had a loose grub on the stepper motor X. It was very unusual and caused many headaches (and layer shifting) until it was resolved. I was able to get quick answers from Sovol’s technicians, who looked at my early failed prints and were able to diagnose the problem. After everything was tightened, the printer began to work as it should.

Sovol SV07 – Leveling

The SV07 has both automatic bed leveling and manual adjustable knobs. To level or tram the bed for the first time, tighten all knobs anticlockwise and then back off by two turns.

Click Configuration, then Machine Level, and Z Calibrate. Click Start. The printer will then move into the center of its bed. Push the raise or the lower nozzle button until it scrapes just the paper. When done, click accept.

Next, you’ll manually level the machine. On the main screen click Configuration, then Machine level. The corners of the bed will be displayed on the touch screen. Tap on the corner to be adjusted and then turn the knob under it until the paper scrapes just the surface.

Click the Home screen to return. Click Configuration and then Machine Level, followed by Bed Mesh. The printer will tap its bed to perform a final calibrated.

You can still tweak the Z height from the Fine Tuning menu while a print is running – but I didn’t need to do that while testing the printer.

Loading the Sovol SV07 with Filament

The SV07 direct drive printer has the extruder built into the tool head.

Warm up the hotend first by selecting Extrude, then Actions. Tape the Temperature Icon and select PLA (or whatever temperature you need). Insert the filament in the runout sensor located near the spoolholder. Then, move down to the Extruder. The tension can be released by pushing the lever of the extruder. Manually push the filament in.

Click Load, and the machine will load the filament into the heated end.

Reverse the process to unload or switch colors.

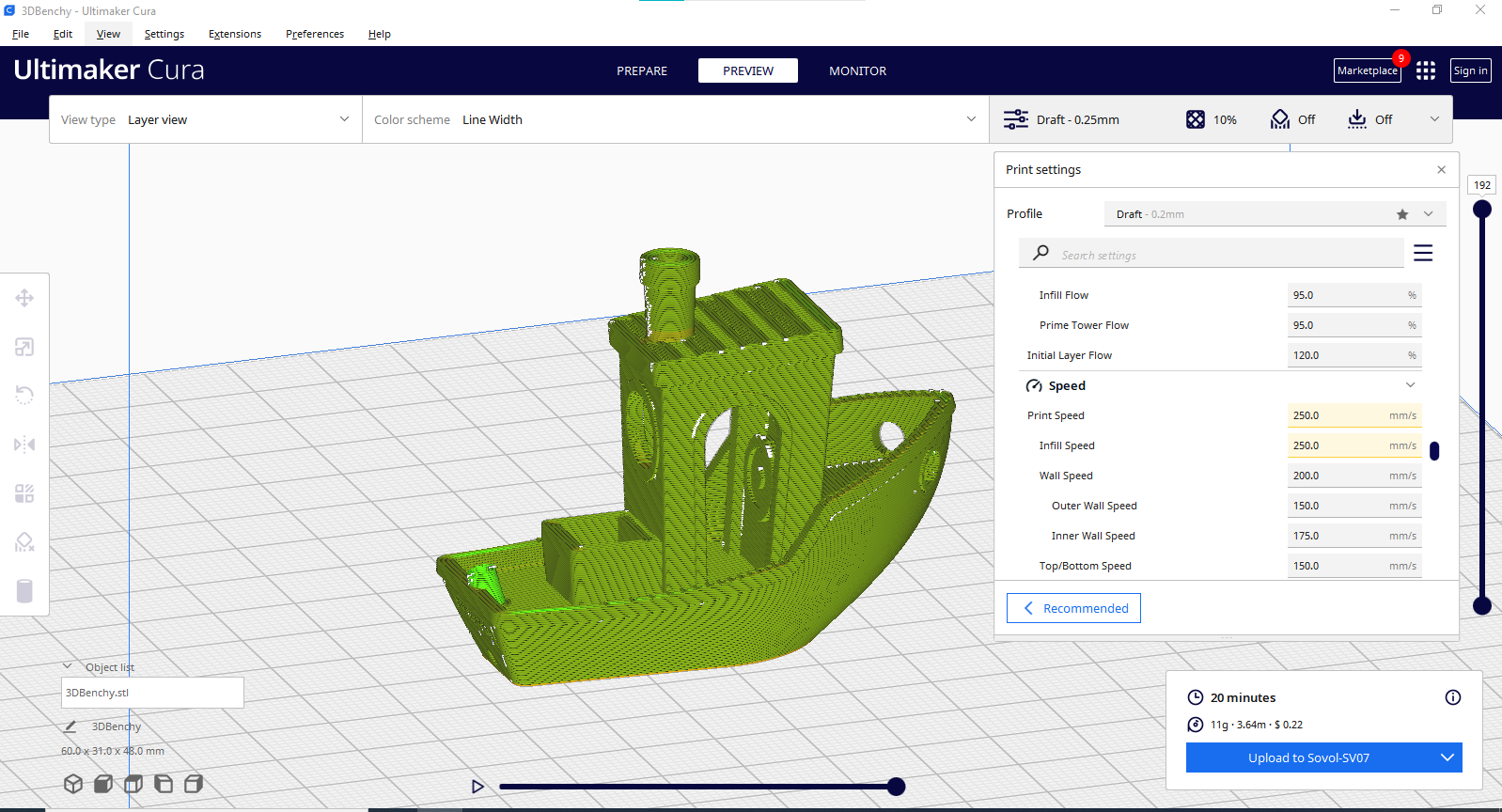

Prepare Files and Software for Sovol Version SV07

The Sovol SV07 is shipped with a Cura 5.0 copy with a profile specific to the SV07. In a rare move, this copy of Cura is otherwise “vanilla” – not rebranded to Sovol – it even found my collection of Cura profiles for other machines and imported them over.

I did encounter one problem: the start and end gcodes in the machine settings were written for an ordinary Marlin printer, and probably copied over from one of Sovol’s other machines. These codes caused conflict and prevented the printing from starting. Once replaced with “START_PRINT” and “END_PRINT” to trigger Klipper’s own macros, the printer worked fine.

No profile is provided for Orca Slicer or Prusa Slicing, but they can be made from scratch.

Sovol SV07 – Printing

Klipper is used by the Sovol SV07 for quick prints up to 500mm/s. The top speed is 500, not average, and it’s usually only used to print infill or travel moves. The default setting is to slow the walls down to 150 for the outer wall and 175 for the inner. The SV07 was able to produce a very good 22-minute Speed Benchy model – very fast indeed when you think that a couple years ago a typical bed slinger might make a Speed Benchy in an hour.

The results were excellent.

Sovol included a generous 200g sample spool, but you’ll soon run out. Our guide on the best 3D filaments will give you some ideas of what to include in your collection.

The first print, of course, was a Speed Benchy cut according to the #speedboatrace official contest rules. This boat uses a.25 inch layer height with.5 inch layer width. The boat also features 2 walls and 3 layers on top and bottom. The Inland Grey PLA printed in just 22 minutes. Despite the speed, there’s no ringing around the porthole, the layers are consistent and the smokestack is crisp. There’s some bridging issues around the top of the cabin and a tiny bit of stringing.

This giant nozzle was printed on a flexi-toy in black Jayo PLA (a budget PLA) and red Amazon Basics Pla (150%), using a standard profile of.2mm and a 250mm/s speed. The Z-seam is what caused the marks in the screw threads, but it was impossible to avoid the roughness on the numbers. The walls and surface are smooth. The “nozzle” printed in 1 hour and 13 minutes, while the “filament” portion took 10 minutes and 20 seconds.

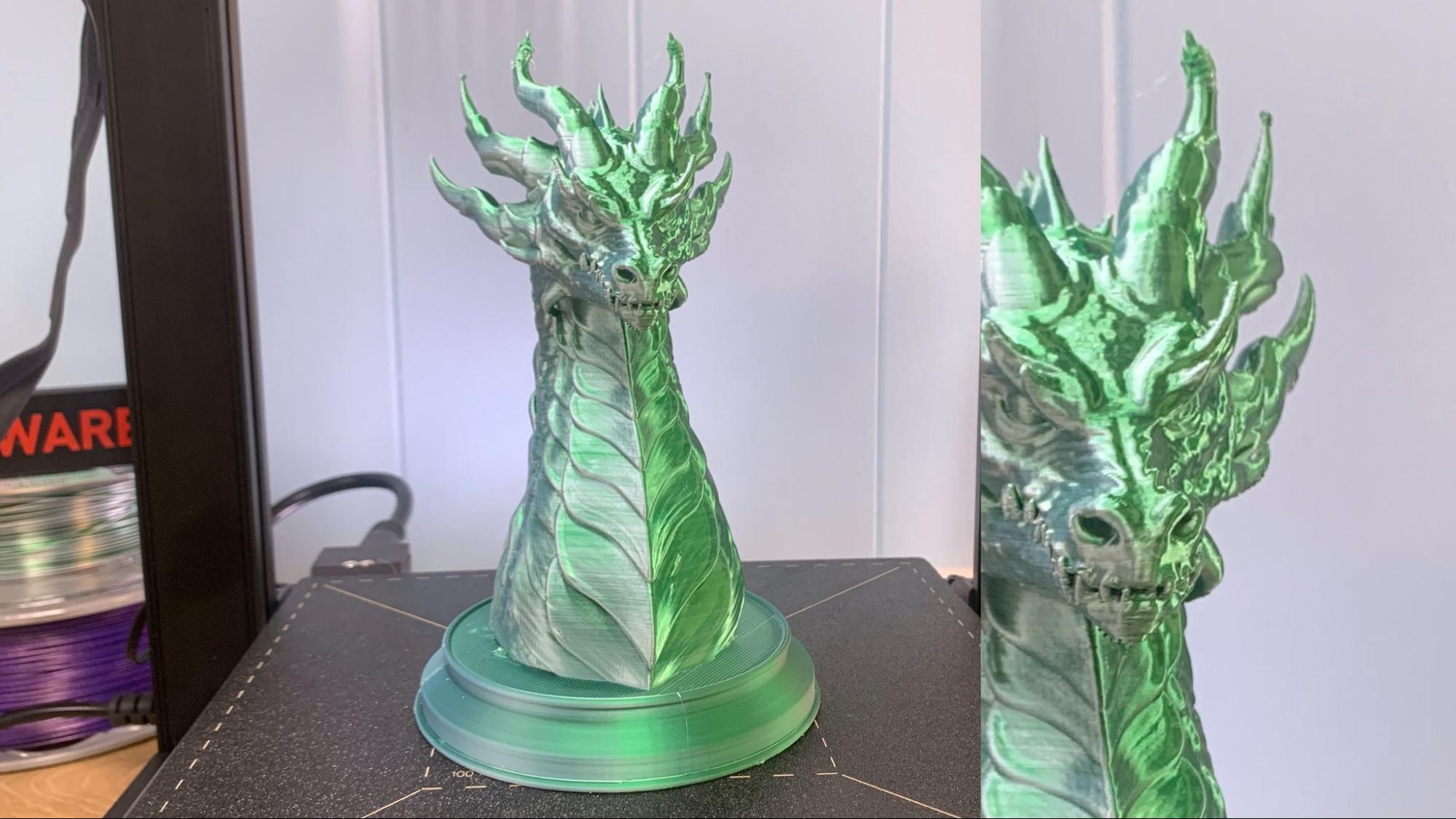

Wekster’s dragon print in Quantum White Green turned out 99% fantastic, with a goober on the very top of the horns where the filament didn’t cool fast enough. It took three attempts to get this print on the bed. This shows how speed can sometimes backfire for a bed slinger. Last try, a raft was added to the print. This finally gave the support enough stickiness to hold it in place. The print took 7 hours and 38 minutes using a.2mm layer at 250 mm/s.

This vase-mode Shell Bottle is printed in PETG without any issues. This was printed with IC3D Blue Razz Recycled PETG. Recycling PETG is better for high speed printers. This print took one hour and eight seconds using a.28-layer height and 250mm/s printing speed.

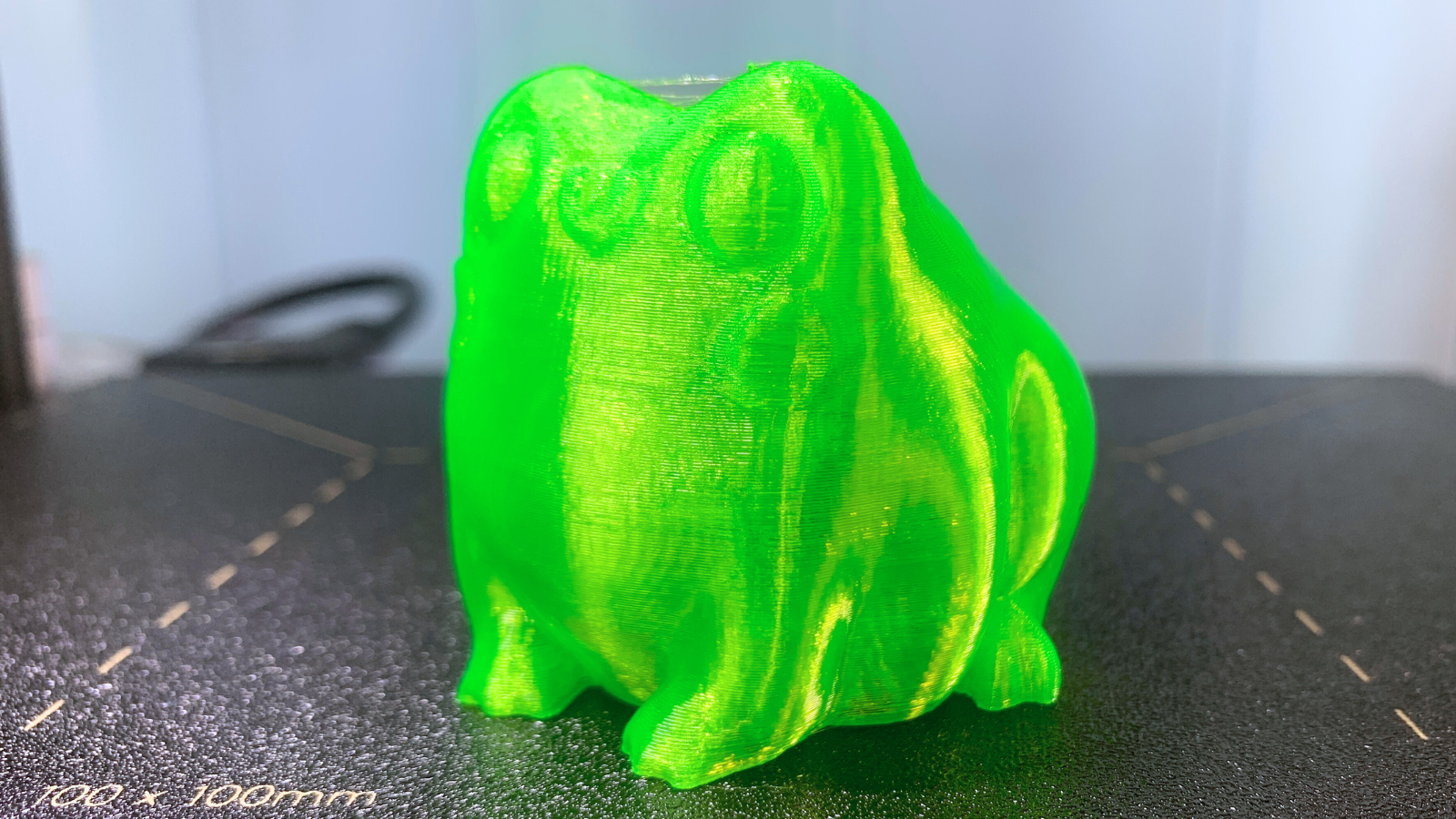

With the direct drive of the SV07, it printed TPU quite well. It was slowing down to 75mm/s but the print came out with even, smooth layers and only a few wisps. The time for printing was 50 minutes and 22 second. This is printed using Matterhackers Green Build TPU at a.2mm layer height.

Bottom Line

We’ve reviewed several printers with Klipper and the Sovol SV07 has been one of the easiest to set up and use. It’s a good choice for anyone who wants to use Klipper but doesn’t want the hassle of setting up Raspberry Pi. It’s easy enough to use to be a beginner’s first printer, but experienced users will also enjoy having full access to Klipper.

It can’t quite go toe to toe with a Core XY machine, which has the added stability of a steady Z axis for smoother prints. The SV07 is a great value at $339. It comes with many of the features we love to see in any printer: dual-Z axis, PEI-coated flex plates on both sides, automatic bed leveling, USB port for adding a camera for monitoring prints. The LED lights are a nice addition and although the cooling system is loud, it does work.

If you can afford a Core XY, we recommend the Creality P1S, a 699$ all-in-one 3D printer that is super fast and enclosed. It’s also our favorite machine for all purposes. If you want a printer that works great right out of the box – and saves you some cash – have a look at the Neptune 3 Pro, currently available for $230.

MORE: Best 3D printers

MORE: Budget 3D Printing

MORE: Best Resin 3D Printers