Liquid metallic in new 3D printing method by MIT

MIT researchers have developed Liquid Metallic Printing, a brand new additive method that may shortly 3D print furnishings and large-scale objects utilizing liquid metallic in a matter of minutes. Their examine has seen the staff 3D print furnishings elements like desk and chair legs and frames with liquid metallic, and the consequence comes by means of as sturdy items of objects. The method of Liquid Metallic Printing begins with a predefined path for the liquid metallic to snake by means of, adopted by depositing molten aluminum. The liquid metallic shortly hardens and kinds the form of the 3D construction, leading to a sooner method to 3D print sturdy furnishings.

pictures and video stills courtesy of MIT Self-Meeting Lab

The MIT researchers say Liquid Metallic Printing can 3D print ten occasions sooner than a comparable metallic additive manufacturing course of, and the method of melting the metallic could also be extra environment friendly than another strategies, provided that metallic can be extra accessible with the abundance of scraps that may be recycled. Skylar Tibbits, the examine’s senior creator, affiliate professor within the Division of Structure, and co-director of the Self-Meeting Lab, says that whereas the progress in quick 3D printing has been promising, compromises nonetheless happen. Within the case of Liquid Metallic Printing, it’s in regards to the decision of the printed objects and their visible aesthetics.

MIT researchers have developed an additive manufacturing method that may print quickly with liquid metallic

Sacrificing excessive resolutions for velocity and scale

The Liquid Metallic Printing method reveals noticeable irregularities with the designs it generates. Tough across the edges, the bumpy surfaces of the outcomes are coupled with some hardened aluminum protruding. The MIT researchers acknowledge this consequence, saying that whereas the 3D printing method can produce parts which can be bigger than these sometimes made with slower additive strategies and at a decrease value, it can’t but obtain excessive resolutions. ‘However most of our constructed world like tables, chairs, and buildings doesn’t want extraordinarily excessive decision. Pace and scale, and likewise repeatability and vitality consumption, are all essential metrics,’ says Skylar Tibbits.

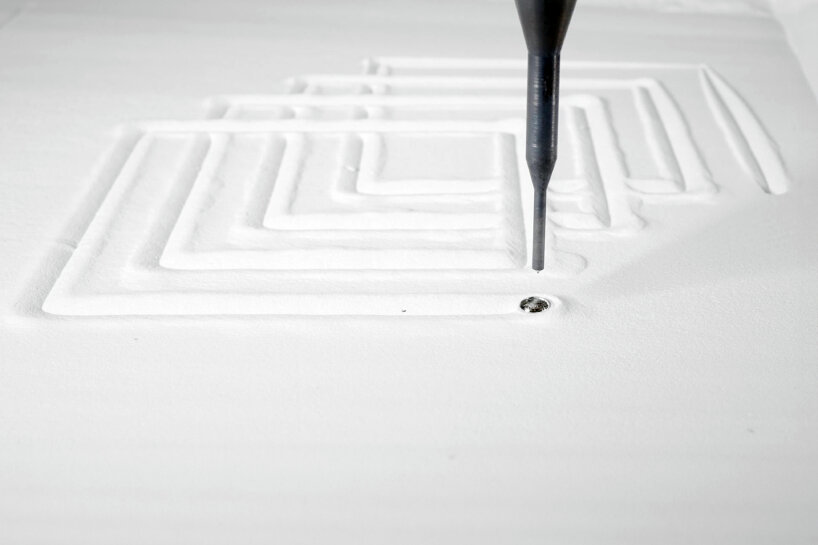

the liquid metallic printing course of entails depositing molten aluminum alongside a predefined path

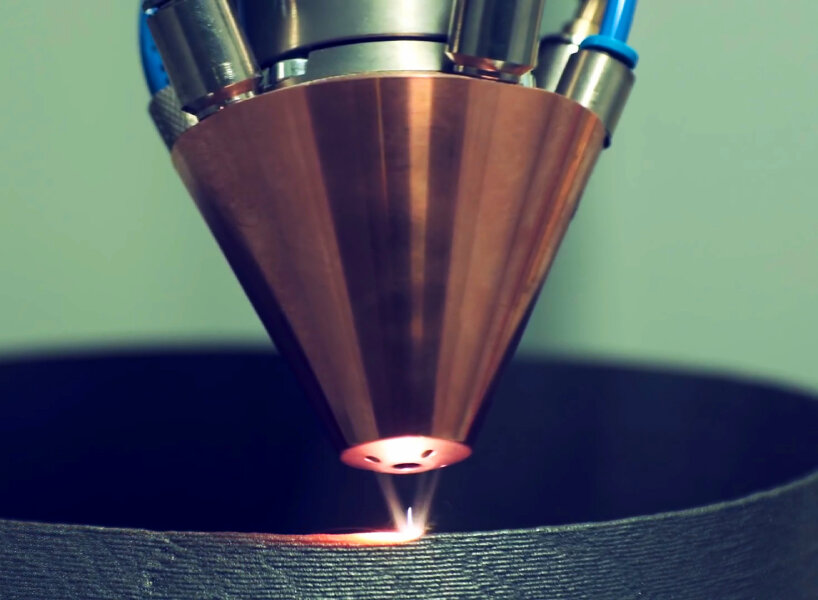

The MIT researchers additionally constructed a machine that may soften the aluminum and maintain the liquid metallic. Items of aluminum are then deposited into an electrical furnace, and the machine injects it into the predestined form or path from a ceramic nozzle. There’s a purpose the researchers selected ceramic because the nozzle’s physique. ‘Molten aluminum will destroy nearly all the things in its path. We began with chrome steel nozzles after which moved to titanium earlier than we ended up with ceramic. However even ceramic nozzles can clog as a result of the heating isn’t all the time fully uniform within the nozzle tip,’ says Zain Karsan, the examine’s lead creator and a PhD pupil at ETH Zurich.

the method can allow the 3D printing of complicated geometries, like in a spiral type

Ceramic nozzle for the 3D printer

Combining these developments, furnishings elements and objects will be 3D printed utilizing liquid metallic in a matter of minutes. For the reason that molten aluminum cools down after a number of minutes, the customers can instantly use the generated merchandise for his or her desired functions. The researchers additionally discovered that the bigger the quantity of aluminum they may soften, the sooner the printer may go. Shifting ahead, the MIT researchers wish to enhance the machine by discovering methods to allow constant heating within the nozzle and forestall the liquid metallic from sticking. A greater stream of the molten materials together with looking for design alternate options to scale back irregular prints can be being thought-about.

the feed fee of the liquid metallic will be adjusted so the fabric is deposited because the nozzle strikes

As Skylar Tibbits says, ‘If we may make this machine one thing that folks may really use to soften down recycled aluminum and print elements, that may be a game-changer in metallic manufacturing. Proper now, it’s not dependable sufficient to do this, however that’s the objective.’ He’s joined on the paper by lead creator Zain Karsan, who’s now a PhD pupil at ETH Zurich; in addition to Kimball Kaiser and Jared Laucks, a analysis scientist and lab co-director. The analysis was introduced on the Affiliation for Pc-Aided Design in Structure Convention and just lately revealed within the affiliation’s proceedings.

the MIT researchers additionally constructed a machine that may soften the aluminum and maintain the liquid metallic