Researchers at ETH Zurich created a 3D-printed ceramic structure for solar reactor cores.

The team is said to have developed a novel 3D-printing methodology that allows the fabrication of porous structures with complex pore geometry. These new graded designs allow solar radiation to be more efficiently transported into the reactor’s interior.

Initial testing shows that 3D-printed solar fuel structures are capable of doubling the production rate compared to isotropic designs.

Climeworks, a spin-off company of ETH Zurich, and Synhelion now work to commercialize and advance this research. Synhelion acquired the license to ETH Zurich’s 3D-printing technology.

The researchers are from the group of André Studart, ETH Professor of Complex Materials, and the group of Aldo Steinfeld, ETH Professor of Renewable Energy Carriers. The Swiss Federal Office of Energy is funding the project.

“This technology has the potential to boost the solar reactor’s energy efficiency and thus to significantly improve the economic viability of sustainable aviation fuels,” explained Steinfeld.

3D printing solar reactor cores

This new development marks the latest step in ETH Zurich’s ongoing effort to optimize the production of renewable energy. The organization has developed technology to produce liquid fuels using air and sunlight. The ETH Machine Laboratory has demonstrated for the very first time the complete thermochemical chain in real conditions.

ETH Zurich’s synthetic solar fuels are carbon neutral, releasing the same amount of CO2 as was collected from the atmosphere during energy production. Solar reactors are the key to this process. This element is exposed to concentrated sunlight via a parabolic mirror, and can reach temperatures of up to 1500℃.

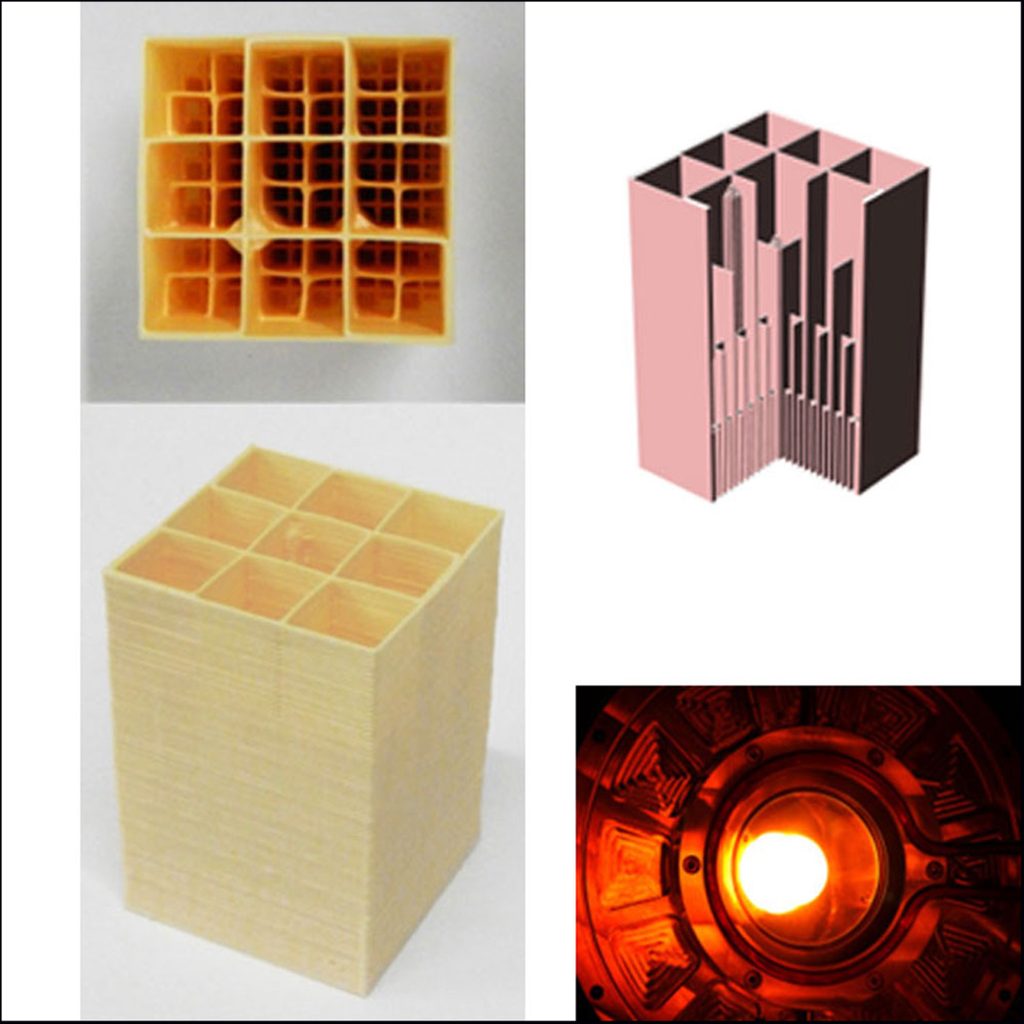

In the interior of the solar-powered reactor, a ceramic porous structure is made from cerium oxide. In this area, a thermochemical process occurs that splits water and CO2 captured in the atmosphere. This process creates a mixture of hydrogen and carbon monoxide called Synthesis gas or “syngas”. This mixture of hydrogen and carbon monoxide can be further processed to liquid hydrocarbon fuels, such as kerosene used in aviation.

This is because these structures have an isotropic porousness, which reduces the force of solar radiation when it enters the nuclear reactor. The inner temperature of the core can be lowered, which will limit fuel yield. To combat this, ETH Zurich’s research has developed a novel methodology that allows structures with complex pore geometries to be 3D printed, enabling solar radiation to be more efficiently transported into the interior of the reactor.

According to ETH Zurich, hierarchically-ordered designs that incorporate exposed channels and pores, and become narrower towards the rear of the reactor, are especially efficient. This design, according to reports, allows incident solar radiation be absorbed across the entire volume of the ceramic. As such, the entire porous structure can reach the 1500℃ reaction temperature, boosting fuel generation.

The research team’s ceramic structures were produced using an extrusion-based 3D printing process. The new ink, which has a low viscosity but a high concentration ceria particles, was also used. These properties reportedly maximized the amount of redoxactive material.

After 3D printing, the ceramic structures were subjected to testing in order to study the interaction between radiant energy and thermochemical reaction. The researchers showed that their hierarchical structures can produce twice the amount of fuel than uniform structures, when exposed to the same concentrated solar energy.

3D Printing and Sustainable Energy

Additive Manufacturing is one of the fastest growing technologies in the sector for sustainable energy.

Researchers at Skolkovo Institute of Science and Technology have developed a new 3D printing technology to create a complex ceramic component for use in environmentally-friendly solid-oxide (SOFC) fuel cells.

The Skoltech team developed their combined micro-stereolithography technology and a common office projector to produce the SOFCs, which incorporate a hierarchical lattice structure. The researchers claim that the lattice structure increases the ionic conductivity and maximizes the power output of 3D-printed fuel cells. This is said be key in accelerating industrial adoption.

HyP3D announced recently a breakthrough on the production high pressure hydrogen with ceramic 3D-printing. The project, with collaboration from French 3D-printing OEM and service bureau 3DCeram aims to demonstrate the viability high-pressure Solid Oxide Electrolysis Cells (SEOC) Technology. HyP3D combines this technology with advanced ceramics to produce high-pressure hydrogen in an efficient and sustainable manner.

Subscribe to the Newsletter 3D Printing Industry Newsletter Keep up with the latest 3D Printing news. You can follow us on TwitterLike our Facebook Page and Subscribe to the 3D Printing Industry Youtube Channel to access exclusive content.

You can find out more about the industry by visiting their website. You can visit the website to learn more about additive manufacturing. 3D Printing Jobs Browse a range of job opportunities and jumpstart your career.

Featured image shows an artist’s impression of a 3D printed ceria structure with hierarchically channeled architecture. Image via Advanced Materials Interfaces. 10, Issue 30, 2023. https://doi.org/10.1002/admi.202300452.