DyeMasion has announced the launch of Powerfuse S PP industrial post-processing system, DyeMansion 360° Digital Service IIoT solution and new collaborations with Nexa 3D, HP and BASF, at Formnext 2022.

“After seven years in business, developing workflow solutions for our customers, I’m thrilled to see that the factory of the future is becoming reality, also thanks to our latest products,” said DyeMansion CEO and co-founder Felix Ewald.

“Together with our customers and partners, we are building different factories for high-volume applications around the world. Formnext demonstrates how anyone can implement our solutions within their factory. Connectivity, automation, and reproducible quality are the prerequisites to successfully future up your factory.”

Powerfuse SPP has been described by many as the best-selling green vapour polishing solution in highly industrial manufacturing. This product can improve the appearance of PP surfaces and even 3D-print them.

The Powerfuse S classic model can be used with most rigid and flexible materials, such as PA, TPU, and ULTEM. While the Powerfuse S PP model is dedicated to processing polypropylene and allows for more applications.

VaporFuse VF44 EcoFluid PP should be used. DyeMansion claims that it is bio-based, 100% biodegradable, and non-toxic. In fact, it shouldn’t contain any PFAS, non-CMR or non-vPvM/PMT.

The high level of automation and closed loop circulation combined with solvent recovery in Powerfuse SPP will allow AM users to reduce costs and increase productivity.

DyeMansion explained that Powerfuse PP was created to offer AM users an integrated solution for the industrial processing and production of polypropylene. It is a widely-used plastic with benefits due to its price, toughness, durability, and chemical resistance.

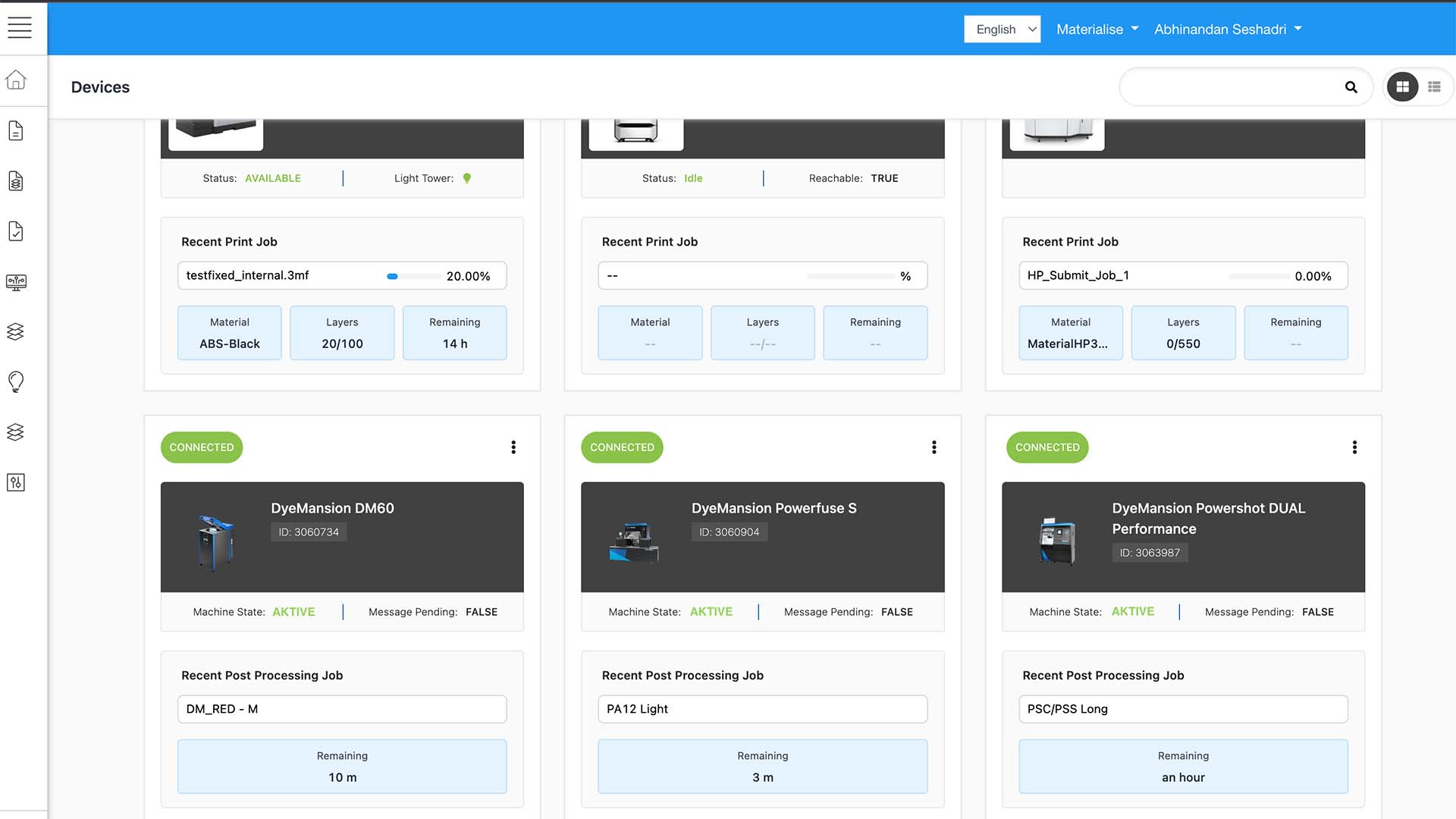

Also announced at Formnext 2022, was DyeMansion’s first digital product, DyeMansion 360°, which will include DyeMansion Workflow Center, DyeMansion Data Connect and DyeMansion Remote Service.

DyeMansion chose Siemens MindSphere as their framework for developing the browser-based DyeMansion Workflow Center. Service should provide live monitoring, custom alarms, run history and other features that are ready-to-use right away via plug-and-play.

DyeMansion Data Connect should offer on-site processing data for MES/ERP software. This ensures that customer data does not leave the premises. Customers should be able to benefit from simplified integration and a complete data set. They also need flexibility and compatibility.

DyeMansion Remote Service is designed to maximize uptime by providing direct troubleshooting and more efficient collaboration through targeted support. It also offers a faster and more efficient remote service that can be accessed from anywhere.

DyeMansion, maker of high-speed industrial and professional polymer printers, has announced in Formnext it will partner with Nexa3D. The collaboration is designed to automate Additive Manufacturing workflows.

This partnership looks to leverage DyeMansion’s automated post-processing hardware, the high-throughput capabilities of Nexa3D’s QLS 820 printer, as well as the printer’s Siemens PLC integration and NexaX for QLS manufacturing software.

“Nexa3D is driving innovation to digitise the supply chain sustainably by making the world’s fastest polymer 3D printers affordable for professionals and businesses of all sizes,” says Nexa3D COO Kevin McAlea.

“It’s only natural that we would partner with DyeMansion, the leading provider of automated post-processing solutions for powder bed fusion, to ensure that our industrial customers can leverage high-throughput manufacturing capabilities from end-to-end as well as reduce their total cost of operation.”

In Frankfurt, HP announced a new partnership. These two companies plan to link post-processing workflows in order to colour and finish white parts manufactured with HP Jet Fusion 5420W.

HP has partnered with DyeMansion to provide connected post-processing workflows that allow for the finishing and colouring of white parts made with the HP solution.

DyeMansion will offer a wide selection of vibrant colours in high quality, consistent colors. They also have different finishes to suit specific applications.

Together with BASF, DyeMansion has released a new whitepaper with the title “Optimising Post-Processing for Ultrasint TPU01” focusing on depowering, vapour polishing and dyeing of Ultrasint TPU01, printed on HP Multi Jet Fusion.

Stratasys also announced that ALM, its new materials partner for the H350 3D printer, will supply its SAF PA12 powder. This powder can be used by AM users as an ready-to-market solution. It has been tested with the Print to Product workflow.