There are four basic stages in additive manufacturing: design, lamination printing, and post-processing. This final step, which is important regardless of the manufacturing technique used, gives the parts a perfect surface finish. A variety of post-processing technologies are used to improve the physical and mechanical properties. A new post-processing technique is set to be a landmark in additive manufacturing. The so-called “Delta” is a machine developed by the startup Reinforce3D using their patented CFIP (Continuous Fibre Injection Process) technology. This solution allows for 3D printed parts to be reinforced by injecting continuous fibres, making them lighter and allowing a better mechanical performance.

Reinforce3D began as a project in the Eurecat Technology Center, located in Catalonia (Spain). Since 2022, a fund of investors has decided to invest in the startup that we know today. It was founded by BeAble Innvierte Kets Fund, Eurecat and Marc Crescenti to develop a new solution for 3D printing post-processing. Blanca Gaarro, its CEO, has led the company to grow and develop its technology over a relatively short period. Delta’s industrial solution, based on the CFIP, will be shown at Formnext 2023 in Frankfurt and aims for a paradigm shift of the post-treatment we have known up to now. We will tell you all about the properties and characteristics of this new system, its applications Delta, the performance of CFIP and the industries that it is aimed for.

Reinforce3D’s Delta allows users to reinforce parts by injecting continuous fibers

A Closer Look at Reinforce3D’s Delta and the CFIP Technology

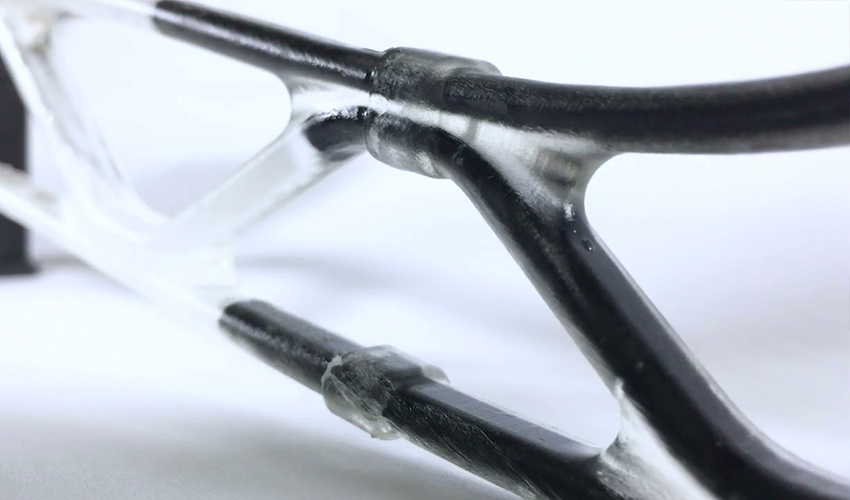

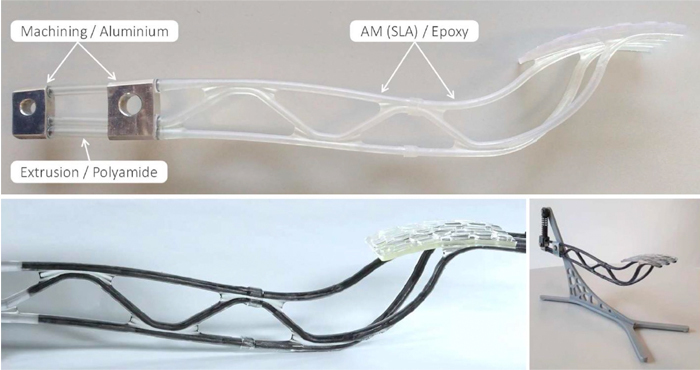

Reinforcing 3D-printed parts with CFIP is a major innovation in additive manufacturing. Delta has made a technology that was only in its early stages a reality. CFIP focuses on improving the properties of parts after the manufacturing process instead of strengthening them during the manufacturing, which is the case with conventional 3D printers. This method involves injecting continuous fibres into parts to improve their performance and strength. In place of short fibers (such a carbon fiber), continuous fibers are injected in pre-designed tubular cavity. These fibers are carried in a resin which cures and strengthens the part.

The advantage of continuous fibers compared to short fibers is that they can improve performance by a factor of ten, not just incrementally. CFIP works with Aramid, glass, and carbon fibers. Reinforce3D also plans to extend its use of natural fibers. The team explains the following: “The Delta machine is an evolution of the technology that adapts it to the rapidly evolving industry, automating the process and facilitating its use in production. CFIP allows for the bonding of components, as well as strengthening them. This creates fiber continuity from one end to the other, resulting in stronger bonds than those obtained with traditional methods, such as adhesives.”

What are the advantages of this method compared to conventional reinforcement in the manufacturing process. The Delta machine is unique in its compatibility and versatility with many additive manufacturing methods. With it, users can turn to more production-focused 3D printing technologies, such as HP’s Multi Jet Fusion, which work with thermoplastic polymers. The Delta machine is compatible and can be used with thermoplastic polymers. You should know that the Delta machine can work with many different materials including metals, ceramics, and plastics.

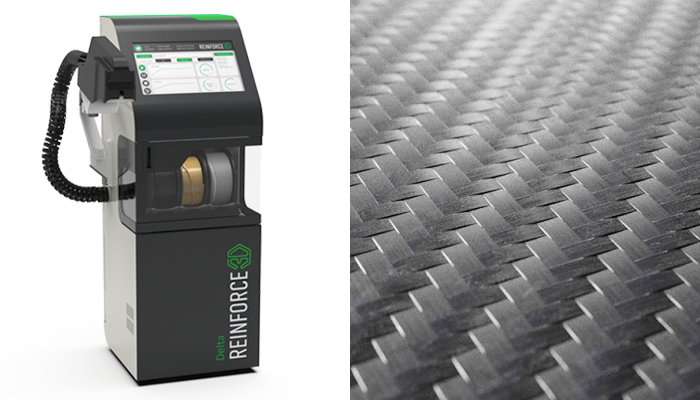

The CFIP can be used with many techniques and materials, including metals and plastics

A further remarkable feature of the machine is the reduction of the material required. Hollow parts can be made that are reinforced with continuous fibres, giving them the same rigidity they would have if not hollow inside. The CFIP is simple to operate thanks to a graphical interface on a touchscreen. Moreover, due to its compact design, it can be used in both laboratories and workshops. This allows it coexist with other 3D printers. It is Industry 4.0 compatible and can integrate with automation and robots systems to create a productive end-toend production workflow.

Reinforce3D’s Role in the 3D Printing Industry

Reinforce3D’s CFIP technology is expected to be a game-changing disruptive innovation in additive manufacturing. The technology is promising for industrial 3D printing because of its ability to significantly improve the performance and quality of 3D-printed parts, as well as its versatility with materials. Delta is a new product that the company has launched to give users a variety of options to improve the properties of their 3D printed products. This machine will be available commercially in 2024. However, we’ve already seen its features and the results it can produce.

Reinforce3D offers a consulting service to companies interested in adopting CFIP. This service covers a variety of areas, including topological optimization and 3D printing processes, injection molding, testing, and cost estimation for industrialization. Whether you want to learn more about the Delta solution or you are looking to request the consulting service, you can visit Reinforce3D’s website HERE.

What do YOU think of Reinforce3D? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Reinforce3D