The Anycubic Kobra 2 Max is an enormous enchancment over its predecessor, however suffers from being overhyped and underdeveloped. It may well print fairly nicely, however its velocity is overstated by Anycubic, which claims it might probably push plastic at 500mm/s. It can not. What it might probably do is a really brisk 150 to 230mm/s, which for the construct measurement is superb.

Our check printer had a tough begin, having arrived with buggy firmware and a barely wonky mattress that dips down within the decrease left nook. Sadly, there’s no guide leveling to appropriate this – solely the sensors – so I ended up shimming the mattress with just a few Submit It notes.

It’s additionally troubling that Anycubic is silent on how all the Kobra 2 lineup has unlocked its new velocity. It appears to be like suspiciously like Klipper – full with built-in resonance testing. Nonetheless, the firmware is inaccessible and no Klipper-like controls are supplied on the menu or management display screen. The printer does supply Wi-Fi connectivity, however provided that you employ the Anycubic slicer and cell app.

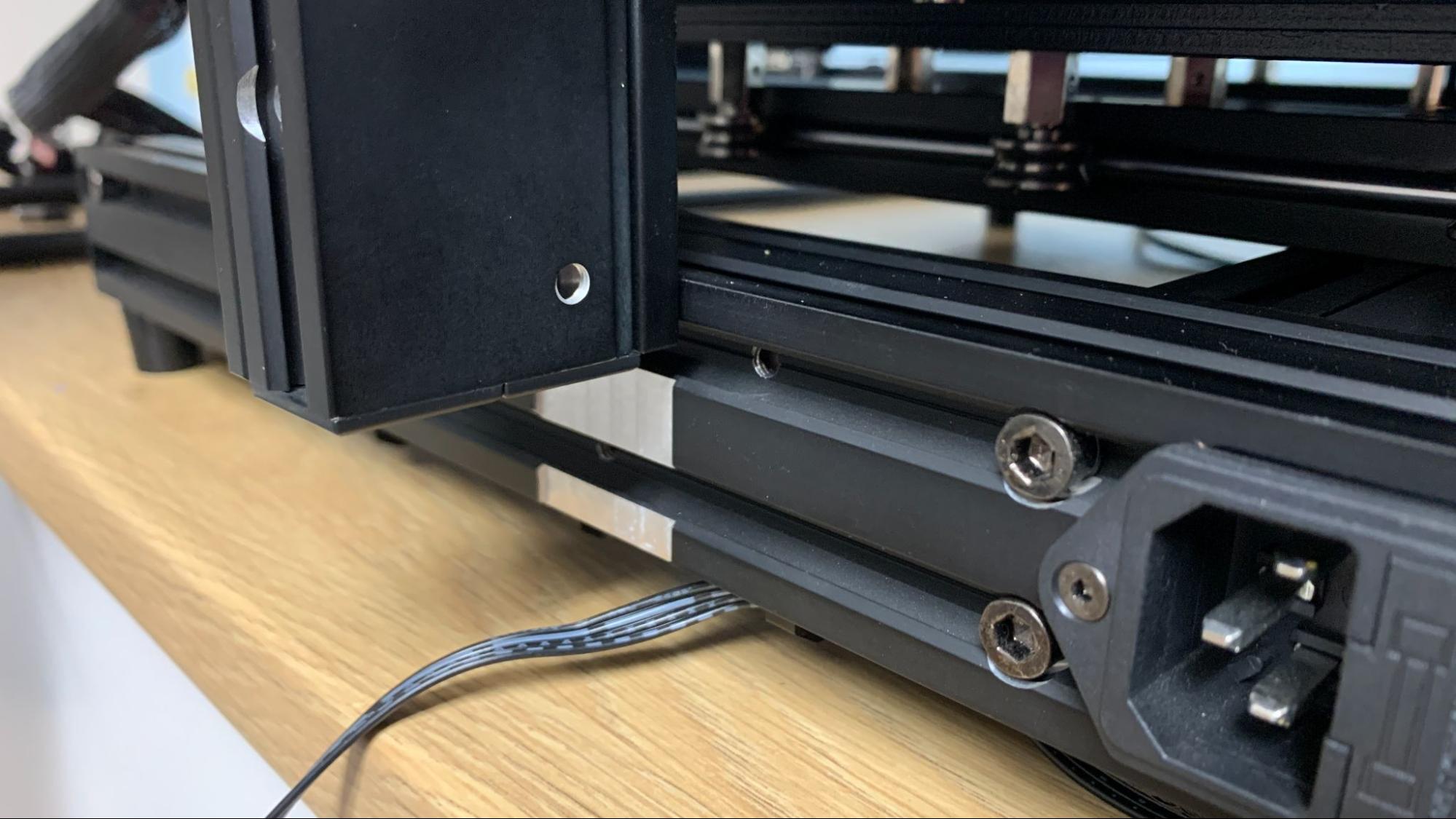

Like the primary Kobra Max, this machine is freaking big. With an enormous 420 x 420 x 500 construct quantity, this Max is nice for cosplay props like helmets and maybe complete shields. However first, you’ll need to measure your workspace and account for the THREE SQUARE FEET of working area it requires. I needed to flip the printer sideways to suit on my IKEA counter – and the spool holder nonetheless hung off into area.

I might nonetheless advocate the Anycubic Kobra 2 Max over the earlier Kobra Max for the rise in velocity and the extra forgiving versatile constructed floor. Regardless of its flaws, it labored nicely on most supplies as soon as I bought previous the early firmware points and found out my very own (slower) velocity settings. The mattress leveling points and lack of quick profiles within the printer’s personal customized slicer prevents me from placing it on the record of finest 3D printers.

Specs: Anycubic Kobra 2 Max

| Construct Quantity | 420 x 420 x 500mm (16.5 x 16.5 x 19.7 inches) |

| Materials | PLA/PETG/ABS/TPU (as much as 260 levels) |

| Extruder Kind | Direct Drive |

| Nozzle | .4mm Proprietary Excessive Move |

| Construct Platform | Textured PEI metal flex plate, heated |

| Mattress Leveling | Computerized + Z top |

| Filament Runout Sensor | Sure |

| Connectivity | USB & Wi-Fi via the app |

| Interface | Shade Contact Display |

| Machine Footprint | 735 x 640 x 740 mm (28.9×25.1 x 29.1inches) |

| Machine Weight | 21 KG (46.3 lbs) |

Included within the field: Anycubic Kobra 2 Max

The Anycubic Kobra 2 Max comes with the whole lot you want to get began: instruments to construct and keep the printer, grease and a USB stick. You additionally get a spare nozzle and small pattern of PLA.

There’s a paper copy of the fast begin information that will help you construct the printer. The printer has pattern fashions within the reminiscence, and the UBB card has a PDF copy of the guide, Anycubic Slicer and a profile for PLA to get you began.

Assembling the Anycubic Kobra 2 Max

Regardless of the dimensions, the Kobra 2 Max is simple to assemble. It ships principally assembled in two massive sections and solely wants a handful of screws and bolts to assemble. 4 bolts maintain the gantry in place, then a brace is hooked up from the highest of the machine to the again. A number of extra screws connect the contact display screen, whereas the spool holder snaps onto the bottom.

Please observe, the Kobra 2 Max has two Y axis belts. You’ll need to be sure that every belt has about the identical quantity of stress for easy printing. It takes about half-hour to rigorously assemble.

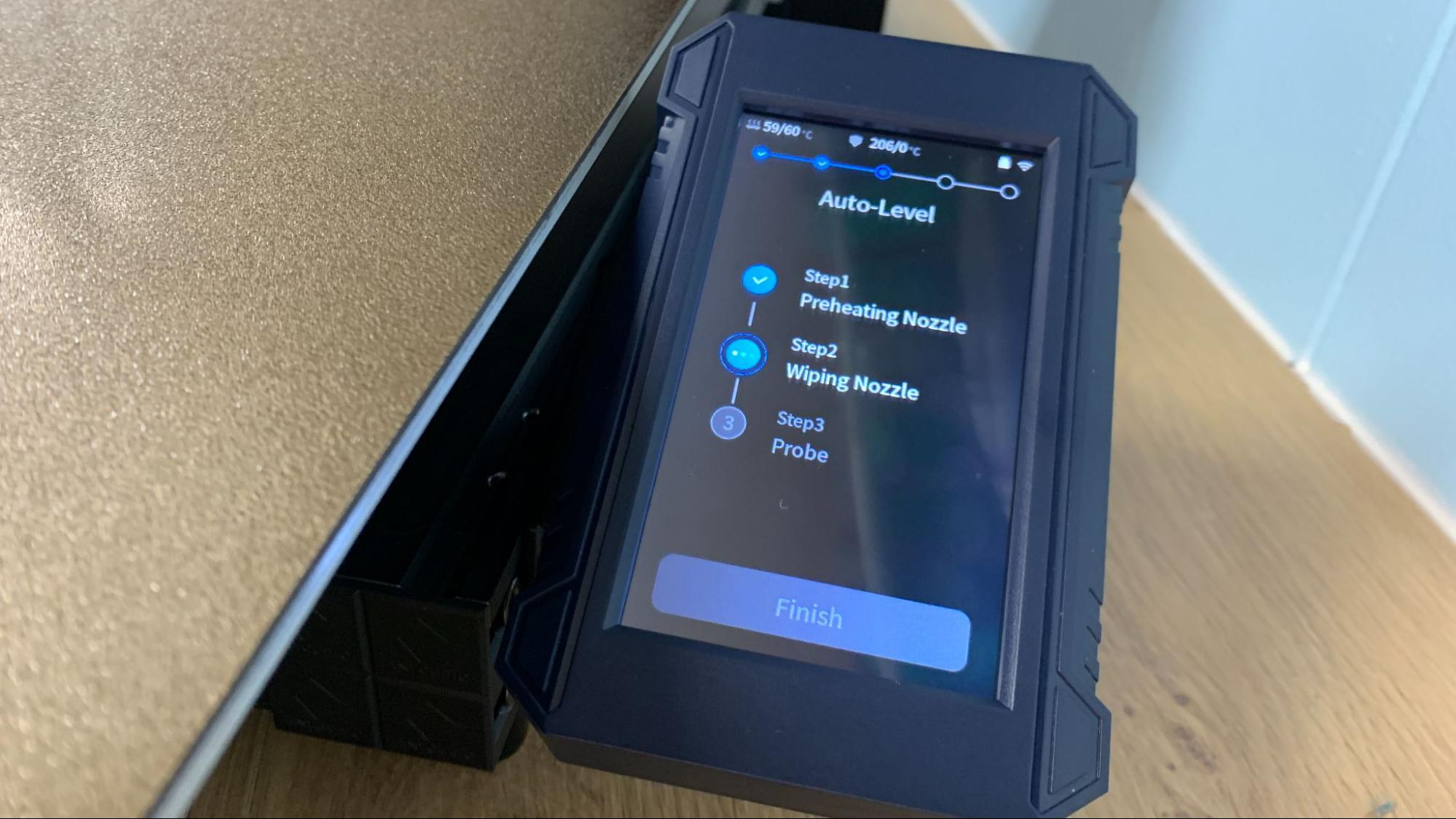

Leveling the Anycubic Kobra 2 Max

The Anycubic Kobra 2 Max has the identical mattress leveling sensors because the Kobra 2, which not solely ranges the mattress but additionally set the Z top. There aren’t any knobs for guide tramming, leaving the whole lot to the automated sensor. If the Z top just isn’t excellent – and our machine was low within the decrease left nook – you don’t have a lot recourse. I needed to shim the mattress with just a few Submit It Notes to get all the mattress stage.

To stage the mattress, choose Management → Auto-level. The machine will house itself, preheat after which double faucet 49 spots in a grid throughout the mattress floor.

Loading Filament within the Anycubic Kobra 2 Max

To load filament, press Put together on the principle menu. Choose Filament. Now choose Filament In or Filament Take away. The machine will now warmth as much as 230 C, taking about 60 seconds. Put your spool on the spool holder, and place the tip of the filament into the runout sensor. Press Filament In and look forward to the filament to be pulled to the extruder, or pinch the stress launch on the entrance of the extruder and push it via by hand. Press Cease when the filament is coiling under the hotend.

Eradicating the filament works the identical, simply in reverse. Let the hotend preheat, choose Filament Take away and let the gears again the filament out. Be happy to manually pull the filament out of the Bowden tube as quickly because it’s left the hotend.

Design of the Anycubic Kobra 2 Max

The Anycubic Kobra 2 Max appears to be like similar to the Kobra 2, with a greater front-mounted blower that is develop into a design characteristic on the hotend. Noticeable enhancements over the earlier mannequin are a metallic PEI flexplate for simple print removing and a direct drive.

The mattress is hard-mounted, which is unlucky as a result of our check printer arrived with a warped print floor. I used to be capable of shim it with just a few sheets of paper, but it surely’s very disappointing to resort to hacks on a brand new printer. The mattress leveling system could be very promising, because it’s added the flexibility to set its personal Z top with the assistance of a sensor within the again nook.

The Kobra 2 Max has an antenna for Wi-Fi, however it might probably solely be used with the Anycubic slicer and app. I couldn’t hook up with the printer over my LAN community, which was once more, disappointing.

The printer could be very massive, and like lots of the new wave of “max” printers, it gained’t match on an ordinary counter. You’ll need to measure your area first and ideally construct it in place. The printer is 43 kilos and tough to get via doorways with the side-mounted spool holder hooked up.

The Kobra Max 2 could also be a “mattress slinger” but it surely’s constructed for stability. It has twin Z rods synced up with a belt, two widely-spaced Y axis rods and braces that maintain the gantry regular. It has silent stepper motors, however you’ll nonetheless hear the followers. It isn’t practically as noisy as a few of the Klipper machines we’re getting now, but it surely’s not a printer for folks simply irritated by white noise.

One other underwhelming change is the transfer from a typical E3D type Volcano nozzle to a proprietary excessive move that’s nearly, however not fairly comparable. This implies you possibly can’t experiment with third social gathering nozzles which will have higher move. The nozzle can rise up to 260 C, sizzling sufficient for many client grade supplies. The mattress can attain temperatures of 90 C, so I might not plan on enclosing this for printing nylon or ABS.

The contact display screen is identical 4.3-inch show Anycubic has used for the final a number of years. The menu continues to be very straightforward to navigate for rookies, with choices in logical places.

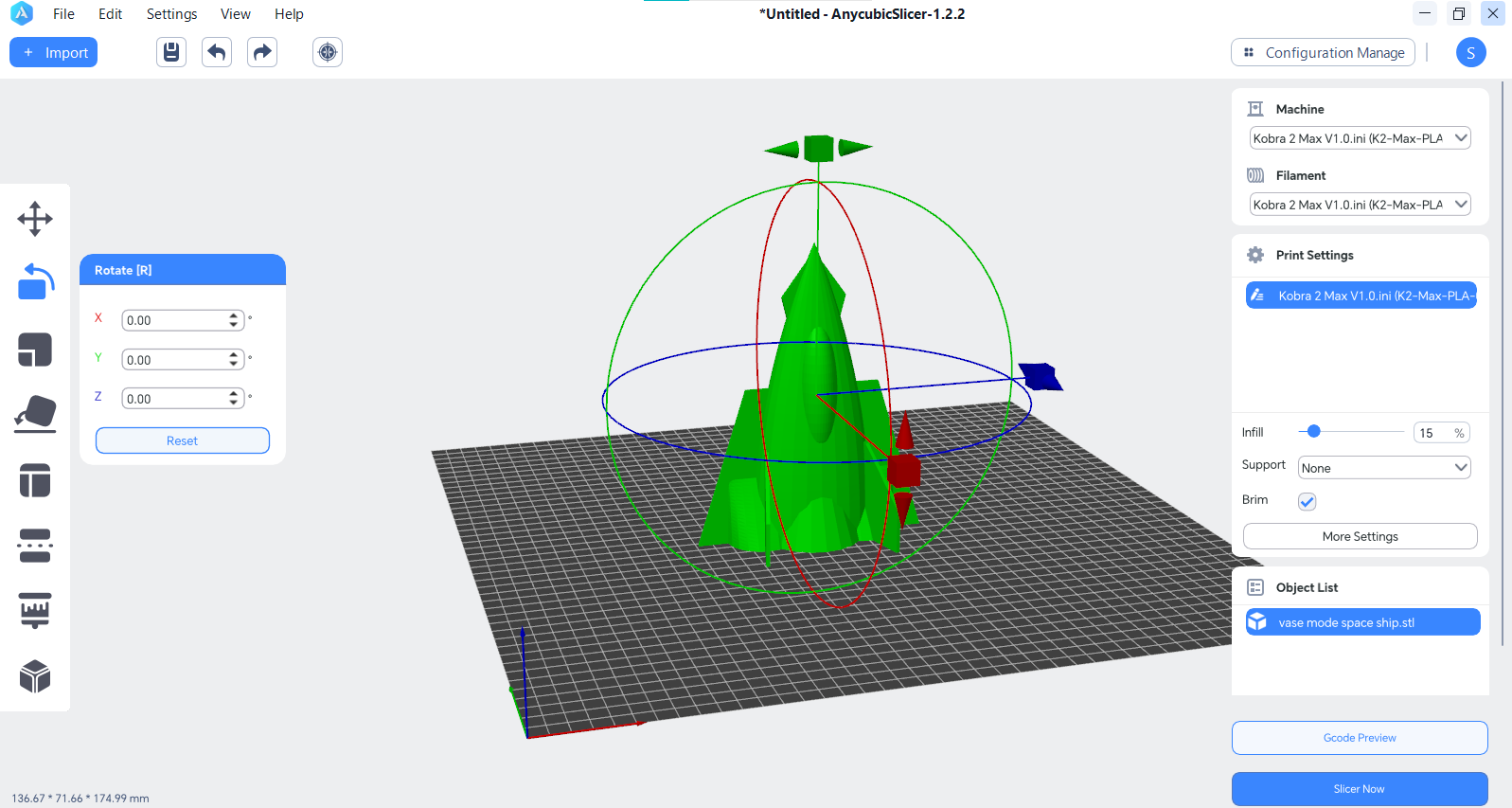

Making ready Recordsdata / Software program

The Anycubic Kobra 2 Max comes with a replica of Anycubic Slicer, which relies off Prusa Slicer. Regardless of being a model new slicer made by Anycubic, the one printing profile was included individually and wanted to be put in myself.

Anycubic has lately launched a cell app to accompany their printers, however I didn’t discover it very helpful. With no digicam or the flexibility to alter the printer’s settings, all it might probably do is announce prints are performed. Anycubic continues to be engaged on the app, and claims you’ll quickly have extra management, the flexibility to watch prints and slice fashions out of your cellphone.

Printing with the Anycubic Kobra 2 Max

Huge printers imply huge prints, so realizing the place to get the finest filaments for 3D printing is crucial. The Kobra 2 Max solely got here with a pattern coil, so that you’ll need to fill up instantly.

After all, you don’t need to print massive objects with the Kobra 2 Max. It’s nonetheless a daily 3D printer – and it might probably actually kick issues into excessive gear for small prints. It was capable of produce a really respectable 18 minute and 4- second velocity benchy utilizing Velocity Boat Guidelines (2 partitions, 3 prime and backside layers, 10% grid infill, a .25 layer top and .5 layer width). The bow was a bit wavy and the layers uneven, but it surely’s nonetheless within the prime ten of our 3D printer velocity hierarchy and on par with the velocity of a Bambu A1 Mini.

All that construct plate was begging for one thing big to print, so I printed an enormous rubber duck out of PLA – you probably have youngsters, you’ll perceive bizarre requests. That is after I realized that velocity and enormous prints don’t combine, because it layer-shifted (see tips on how to keep away from layer shifting in your 3D prints) after getting over a kilo of PLA on the mattress. I slowed down the overly optimistic journey speeds and bought a reasonably first rate print when you don’t look too laborious on the Z seam, which continues to be a multitude.

In all places else, the print is clear. The little duck (at 100%) took 1 hour and 35 minutes, whereas the massive duck (at 400% and 425mm tall), 22 hours and 43 minutes. Each have been printed at 230 mm/s with .28 layer top and lightning infill. The failed print ate into my provide of Inland Yellow Pla+, so we switched to Printerior orange midway via.

Subsequent up was a sensible print: a clip for a motorbike air pump. This was made in Tinkercad to customized match the bike body and the dimensions of the pump. The print turned out splendidly easy with no stringing. 42 minutes and 12 seconds, at a .2 layer top and 230 mm/s. I printed it in Greengate recycled Purple Reign PETG.

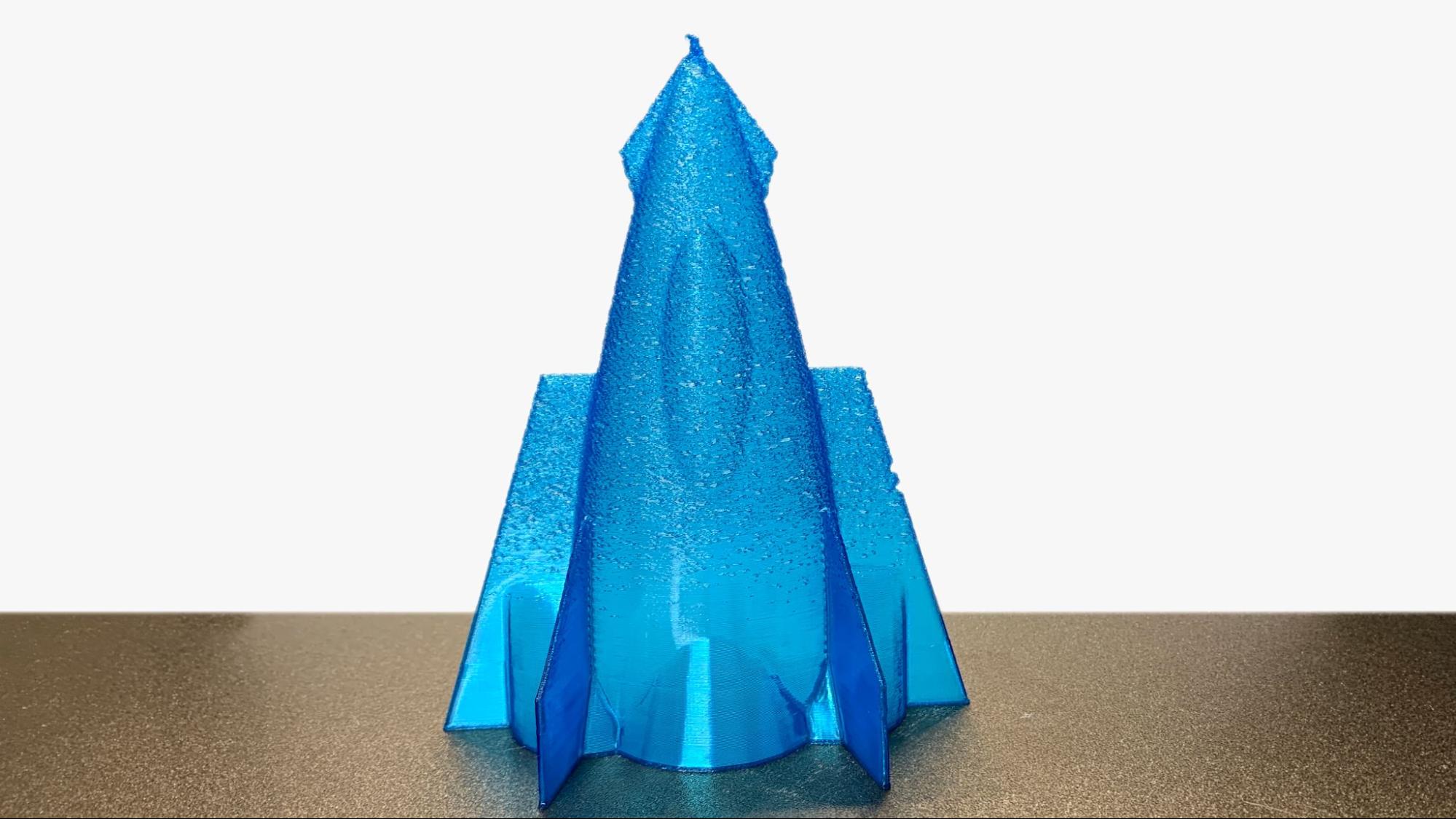

TPU was much less profitable. On this vase mode print, it began off very easy and clear, however then began to beneath extrude because the layers took much less time to finish. This was printed at a 100 mm/s velocity utilizing a .28 layer top, and took 1 hour and 37 minutes to print.

Backside Line

The Anycubic Kobra 2 Max is an enormous machine fairly priced at $569 and at the moment on sale for $519. It’s a great match for prop makers and cosplayers who need to make massive costume items while not having to slice up their printers. You do need to be within the temper to tinker with the slicer to get the most effective stability of velocity and precision.

It’s an enormous enchancment over the earlier Kobra Max, and far quicker, even when it isn’t sensible to go pedal to the metallic. The PEI mattress sheet and Z top sensor are welcome additions.

Nonetheless, the entire printer feels rushed to the market, particularly as I needed to maintain on to this evaluation for a pair months whereas Anycubic addressed a deadly firmware flaw within the early model. Even with the wait, it nonetheless lacks any notable options within the promised app and the slicer feels second hand at finest.

If you need an enormous printer that works nice out of the field, the Elegoo Neptune 3 Max continues to be your finest wager, and fairly a steal at $409. It stays our Editor’s alternative for big format printers.