The meat industry, along with dairy production, is responsible for 83% agricultural land use. It also produces 18% of greenhouse gases including methane, nitrous oxide, and 83% of the country’s total greenhouse gas emissions. What’s more, a study from the University of Oxford found that eating a vegan diet could cut an individual’s carbon footprint by up to 74%, making it the single best way to help the planet. This may seem obvious, but it is not. Despite these stats, meat still features prominently in many cuisines across the globe. Many of us couldn’t imagine our lives without it. Substitutes for meat have been growing in popularity in recent years. They are especially those that mimic the taste and texture of meat. Lab-grown meat is less well-known. Today, Clarisse Beurrier, of Animal Alternative Technologies, will be introducing you to her company based in Cambridge, UK. She uses 3D printing to produce cultured meat. Continue reading to find out her thoughts and motivations about the meat industry.

3DDN: Could your company introduce itself and discuss 3D printing?

Clarisse Beurrier is my name and I’m the CEO and co-founder of Animal Alternative Technologies. We are an engineering and B2B startup located in Cambridge that focuses on increasing the production of cultured meats to ensure food security and sustainability. 3D Printing plays an important role in this exciting sector of Cellular Agriculture. Cellular Agriculture is the production of agricultural products using cells rather than animals. Animal Alternative Technologies already uses 3D printing for many purposes, especially for rapid prototyping or the creation of custom parts.

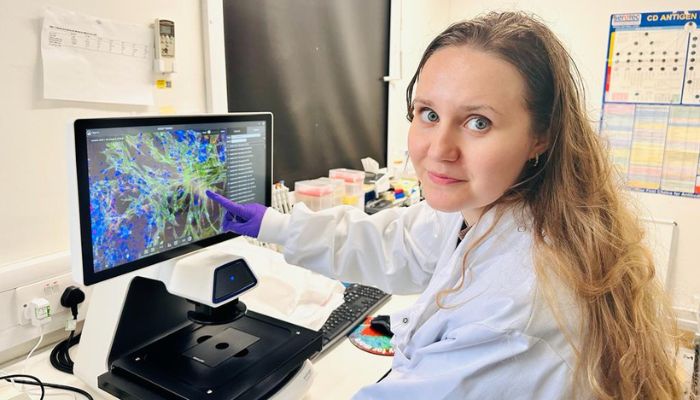

Clarisse Beurrier is the CEO of AAT

My goal is to make cultured meat production affordable to everyone, while also making it possible for others to innovate meat. We have developed scalable industrial processes that can be used to produce the main types of mammalian meats.

3DN: What are your motivations for starting AAT?

Livestock is the most common land use on the planet. This makes it a major contributor to greenhouse gas emissions as well as the greatest source of water pollution, deforestation and demand for antibiotics. Cultured meat is an ethical, sustainable and safe alternative to animal husbandry. Unfortunately, commercial production is not yet possible. Additionally, there are high barriers to entry, such as ~$100M and 5 years needed for R&D that prevent widespread adoption. AAT removes these barriers to entry by performing all necessary R&D and offering pre-approved, end-to-end cultured meat production systems that are also viable alternatives to larger factory farms.

We believe that we can contribute to the already established trend of moving away meat. For example, France and the UK both have high levels of meat consumption (both above the recommended limit). For a long time, meat has been an emblem of masculinity and social status in these two countries. The younger generation has been avoiding meat for the last 20+ years due to health, ethical, and environmental concerns. There has been an increase in the availability of alternative protein options on the market, both from established companies and new startups such as HappyVore. Also, supermarket chains have their own offerings. It seems there are more options for white meats in the UK, while France traditionally consumes more red meats.

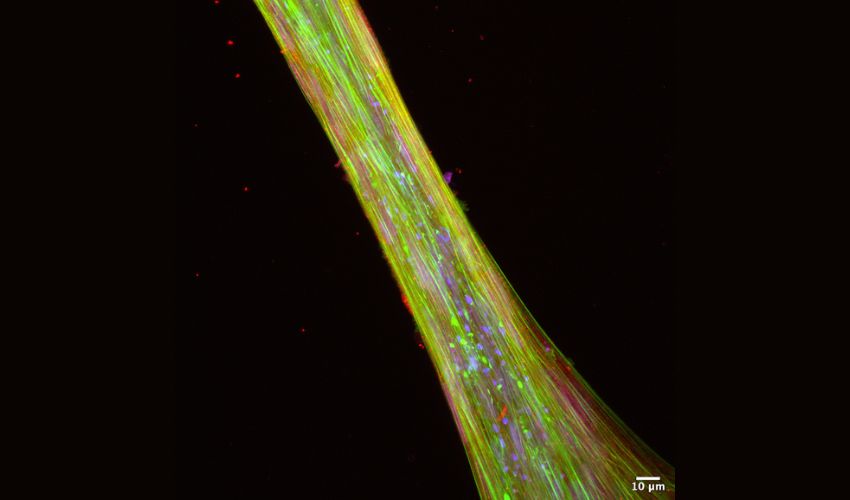

Ovine muscle

3DN: What is additive manufacturing and how does it affect animal alternatives technologies?

AAT uses additive manufacturing primarily to create parts for prototypes of our bioreactors (machines that are similar to beer fermenters, which allow cells to be grown by providing the right conditions like temperature and nutrients). . Because machines that are available on the market, even the smallest ones, cost more than 20,000 Euros and cannot produce cultured meat, we have access to engineers and workshops. They are not only poorly adapted to the requirements of the cells, but also to the new industry. This new industry can only succeed if production costs are comparable to conventional meat (as it comes from the factory). It can also be used to print molds of materials (plants and composites), which act as a framework for cells to attach to and turn into muscle/fat, and to make certain parts of our biosensors.

3D printing: Does 3D printing impact the way we eat meat?

Because of its versatility, 3D printing is able to play an important role in many aspects of alternative meat production and development. AAT uses 3D printers to build custom parts to support cultured meat production systems. Novameat, however, uses it to produce better meat textures and flavours. Aleph Farms, another cultured meat startup made a prototype of ribeye using live cells directly bioprinted. I’m also interested in seeing if bioprinting technology can evolve and be a viable option for at least part of a large-scale cultured meat production process, as it could increase our options and flexibility. These two technologies are both so new and offer so much potential that they are only the beginning for a symbiotic partnership.

Clarisse Beurrier and two founders of the cultivated fish area Aaron from Fisheroo, YiTing before at Big Idea Ventures (the largest investor in the alt-protein space) and Xixi (from left to right).

3DN: Who is the consumer? What do you think will happen to this?

There has been some preliminary market research on cultured meat’s prospective customers. These people are mostly traditional meat-eaters and, in turn, more likely to have middle-aged men with greater incomes. They want the same meat and are attached to the traditions and social customs associated with the products. They also value taste more than other factors. Cultured meat is a product that appeals to people who enjoy novelty and want an edge. They are interested in technology and can be a part of the technical leadership within their companies.

Cultured meats will be initially priced the same as organic meats, and thus sold as a premium product. As technology improves, costs will be able to fall further. With a greater product range and lower prices, I believe the cultured meat industry can attract more customers from all socio-economic backgrounds, cultures, and other countries.

3DN: What is the best way to encourage acceptance of cultured beef among the public.

To build trust in a product, I believe that transparency and disclosure is crucial, just as with any new technology. This is especially true in this case because we are discussing food. The EU’s Novel Foods Regulation is a stringent process that every cultured meat company needs to go through to be allowed to sell their products in the EU, so consumers can be assured of the highest standards of quality and safety will be met. Cultured meat is likely to be more expensive than livestock meat. Therefore, it is important that customers understand the differences and compare it to other meats.

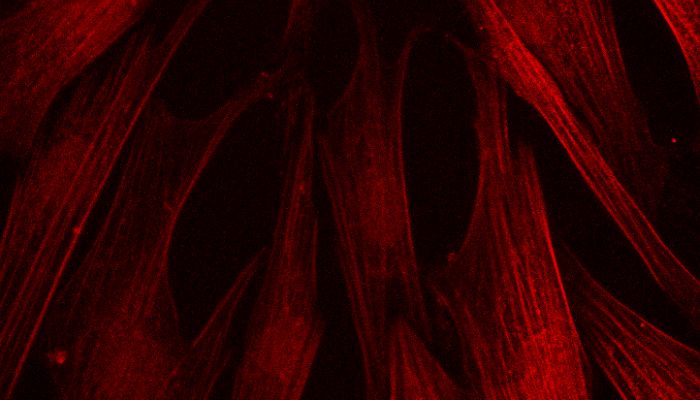

Animal Alternative Technologies’ bioreactor prototypes (right) are used to make lab-grown meat

3DN: Last words for our readers?

We appreciate your curiosity and interest in this area and would love to hear about it! Are you thinking of other applications for 3D Bioprinting in Foodtech? How do you approach scaling up cultured meat so it is cost-competitive with animal farmed meats Find out more information about Animal Alternative Technology by visiting our website HERE, or reading our research HERE.

What do YOU think of Animal Alternative Technologies’ (AAT), work on cultured beef? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Animal Alternative Technologies/AAT