US-based startup Rosotics specializes within the improvement of 3D gear, with a selected concentrate on metallic additive manufacturing. Its objective? To supply producers the biggest metallic 3D printer ever imagined on at this time’s market. Referred to as the M1, this manufacturing platform affords spectacular construct volumes – starting from two meters in diameter to 10 meters in peak. It’s able to designing elements as imposing as fairings or tanks, assembly the necessities of sectors corresponding to aerospace, maritime and vitality. We spoke with its CEO, Christian LaRosa, to search out out extra about how this machine works and Rosotics’ ambitions.

3DN: May you introduce your self and Rosotics?

Hello, I’m Christian. I’m the CEO and Product Architect of Rosotics, a venture-backed industrial robotics and manufacturing R&D company growing and working large-scale metallic additive manufacturing programs for the manufacturing of huge structural {hardware} (such because the tanks, domes, fairings, and interstage of rockets). Our system, the M1, is deployed as the biggest commercially obtainable metallic 3D printer on this planet, serving within the aerospace, vitality, and marine industries.

The Rosotics Workforce

3DN: Why did you determine to create Rosotics?

Rosotics was based with the said objective of enabling 3D printing’s usability as in heavy trade. Our trade, in small-scale, has superior very quickly previously decade and has revolutionized how elements and elements are manufactured. We imagine that the large-scale phase as effectively should be capable of entry the capabilities of 3D printing, within the supplies and efficiency thresholds it processes every single day, and we developed a platform expressly to permit for that functionality.

3DN: May you inform us extra about your manufacturing platform? What makes it distinctive?

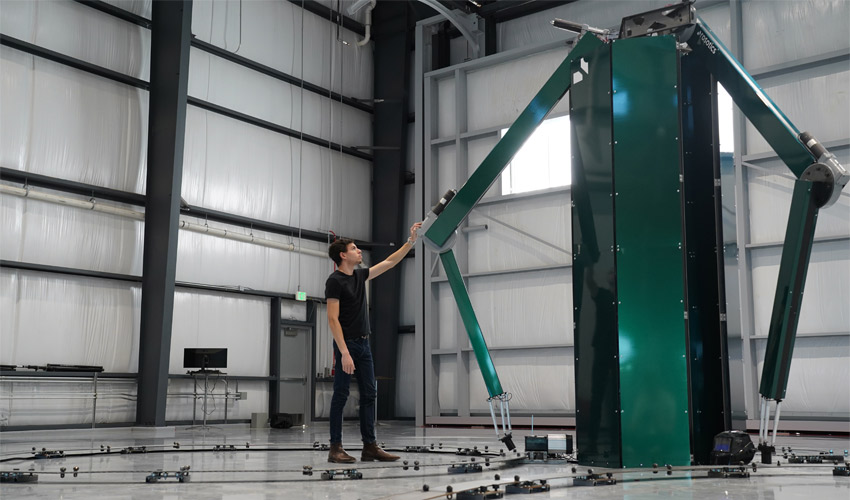

Many firms in additive manufacturing have completely different definitions of the time period ‘large-scale’. We’re fairly clear in ours, we don’t use the phrase ‘elements’ right here – we print ‘constructions’, as a result of the system operates at a really excessive mass movement price to print very heavyweight {hardware}. Our platform, the M1, serves as the biggest commercially obtainable metallic 3D printer on this planet, printing from simply 2 meters in diameter to effectively over 10 meters in peak and diameter.

On the coronary heart of our platform is an internally developed induction-based course of; which doesn’t make the most of a laser of any sort, permitting for a considerably increased volumetric print pace in addition to working on far much less of a footprint when it comes to infrastructure and energy demanded. The Speedy Induction Mass Excessive (RIME) method additionally processes commercial-off-the-shelf (COTS) wire feedstock, eradicating the necessity for harmful powderized metals, whereas sustaining the identical degree of aerospace-grade efficiency.

The M1 manufacturing platform

3DN: What sectors are you concentrating on?

M1 is designed to produce the aptitude to additively manufacture not solely aerospace {hardware}, however that of wind generators, marine vessels, or any sufficiently tough metallic construction that may historically be machined or cast. Our platform is certified to serve most if not all main structural manufacturing of those scales in a single automated platform. It is a functionality usually served of a number of impartial tooling programs.

3DN: How do you see metallic AM within the subsequent 10 years?

Many think about 3D printing as an trade that had ‘peaked’ a number of years in the past, when this isn’t the case. The advantage of 3D printing has not been realized but; that’s when you’ll be able to speed up what was historically 3–4 years of testing campaigns predicated on very lengthy bespoke lead instances, all the way down to underneath a 12 months. What this trade will permit, upon the emergence of accessible large-scale print capabilities, is a type of manufacturing optimization not seen because the days of Henry Ford and the primary meeting line.

The M1 allows large-scale manufacturing

3DN: Any final phrases for our readers?

We worth builders. In the event you attempt to construct, or are already engaged on a breakthrough product that may very well be accelerated from M1, we’d like to be in contact. Yow will discover out extra about Rosotics HERE.

What do you consider the 3D printer developed by Rosotics? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to enroll in our free weekly E-newsletter right here, the newest 3D printing information straight to your inbox! You can even discover all our movies on our YouTube channel.

*All Photograph Credit: Rosotics