On this version of Sliced, the 3D Printing Trade information digest, we cowl the newest enterprise developments, partnerships, and acquisitions within the additive manufacturing sector.

As we speak’s version options new supplies, partnerships, and enterprise offers.

Learn on for the information and updates from Erpro3D, Arkema, Photocentric, L3 Harris, Chromatic 3D, and extra.

Enterprise offers and acquisitions from Erpro3D, Plastigen, Massivit 3D, Stratasys, and extra

Diving into enterprise offers and acquisitions, Erpro 3D Manufacturing facility has achieved a major milestone by creating an built-in provide chain in Europe to supply customized elements utilizing Arkema‘s bio-based elastomers, Pebax, and Rnew. These revolutionary elastomers, partially derived from renewable castor beans, are famend for his or her use in high-performance sports activities sneakers, shopper electronics, and medical gadgets. Now, Erpro 3D Manufacturing facility can manufacture large-scale 3D printed elements from these supplies utilizing selective laser sintering (SLS) expertise, presenting new prospects for patrons. The collaboration with Arkema marks a groundbreaking enchancment over conventional TPU supplies, providing enhanced efficiency and the usage of renewable sources. Quickly, prospects can conveniently order elements comprised of the brand new Pebax and Rnew powder by means of the user-friendly Easy3D platform.

Adopted by Plastigen, Chile’s main industrial polymer provider and elements producer, has joined the Roboze 3D Components Community, an AM manufacturing community developed by Roboze, an industrial 3D printing programs supplier. By this collaboration, Plastigen will provide certified 3D printed elements on-demand, utilizing Roboze‘s superior additive manufacturing programs and supplies to help Chilean producers and OEMs. As Chile embraces Trade 4.0 ideas, reminiscent of additive manufacturing, this partnership presents a possibility for native producers to optimize provide chains, cut back lead occasions, and improve operational effectivity. By embracing localized 3D printing, Chile can advance in direction of sustainable and revolutionary manufacturing practices, lowering waste and vitality consumption.

3D printer producer Massivit 3D has launched a groundbreaking resolution for composite manufacturing by means of additive-manufactured mandrels. Additively manufactured mandrels provide benefits over conventional strategies, enabling complicated designs with lowered lead occasions and decrease prices. Massivit’s proprietary printing course of, using water-breakable materials, produces sturdy and sturdy mandrels that crumble in water, facilitating simple elimination from the ultimate product. The Massivit 10000 AM system, using Forged In Movement (CIM) expertise and Gel Dishing out Printing (GDP) methodology, permits direct casting of the mould right into a 3D printed sacrificial shell. This disruptive expertise revolutionizes composite half manufacturing, providing larger high quality, reliability, and effectivity in numerous industries.

3D printer OEM Stratasys has unveiled GrabCAD Print Professional, a brand new software program designed to optimize the print preparation course of for its polymer 3D printers. Built-in with high quality assurance performance from Riven, a Stratasys acquisition, the Professional model is tailor-made for producers aiming to effectively produce end-use elements at production-scale volumes. The software program gives superior capabilities, together with computerized warp correction, standardized manufacturing templates, improved price estimation, label technology, and 3D array options. GrabCAD Print Professional additionally introduces third-party companion plug-ins, with AlphaSTAR and Castor among the many preliminary companions. Stratasys goals to help prospects in scaling up their additive manufacturing capabilities for end-use elements manufacturing.

French-Swedish industrial robotics startup ADAXIS has turn out to be an Affiliate Member of the 3MF consortium. The 3MF format ensures knowledge integrity and eliminates fragmentation by encompassing all crucial mannequin, materials, and property info inside a single archive. ADAXIS will work with different members to optimize the 3MF format particularly for Robotic Additive Manufacturing, aiming to drive developments in additive manufacturing expertise and improve robotic programs’ capabilities within the business. This affiliation underscores ADAXIS’ dedication to excellence, innovation, and collaboration, contributing to a extra environment friendly and sustainable future for manufacturing.

Moreover, Italian motorbike exhaust producer Termignoni has revolutionized its manufacturing course of with Stratasys’ industrial FDM additive manufacturing resolution. By adopting the Stratasys F770 3D printer in-house, Termignoni drastically lowered time to marketplace for its motorbike exhausts from weeks to days and minimize manufacturing prices by 50%. The massive construct chamber of the F770 permits the complete element to be 3D printed as a single piece, eliminating inaccuracies and inefficiencies related to gluing elements collectively. Utilizing ASA thermoplastic and soluble help supplies, Termignoni achieved exceptional stability, floor look, and post-processing effectivity, enhancing its aftermarket elements improvement and maximizing gross sales alternatives.

Ernesto Marinelli, Basic Supervisor and Product and Technical Director at Termignoni, says prototyping usually represents a 3rd of the event time. “Having the ability to 3D print rapidly, take a look at, make revisions, and so forth creates a particular time benefit,” he says. “Now, the method is less complicated, quicker, and due to this fact less expensive.”

Asahi Kasei is investing in Castor Applied sciences, an Israeli 3D printing software program startup, aiming to capitalize on the fast-growing 3D printing market. With annual development projected to achieve 24%, the necessity for optimized technical companies and quicker buyer response occasions is essential. Castor’s software program makes use of proprietary algorithms to robotically choose appropriate elements for 3D printing from CAD drawings and suggest form modifications, streamlining the manufacturing course of. Asahi Kasei’s funding will enable for synergies between its CAE technical service for plastic merchandise and Castor’s software program, enhancing help for buyer product design and improvement with extra superior simulations.

“By this funding, we’ll additional examine the synergies between CASTOR’s software program and Asahi Kasei’s CAE experience,” stated Yukihiro Bann, Senior Basic Supervisor for Enterprise Technique and Advertising and marketing, Mobility & Industrial SBU at Asahi Kasei Corp. “We purpose to offer our prospects with extra superior and automatic real-time simulations, in addition to to develop the vary of technical companies that each firms can provide.

Metallic 3D printer producer SLM Options and Chromalloy are partnering to speed up additive manufacturing manufacturing within the aviation and vitality sectors. Chromalloy, a world aviation and vitality expertise firm, has chosen SLM Options as its steel additive manufacturing companion and purchased the SLM 280 machine. Leveraging SLM Options’ open-architecture expertise, Chromalloy will develop high-quality steel elements, with a concentrate on its proprietary LifeX services and products that optimize engine overhauls. Because the main unbiased provider of aftermarket options for jet engines and fuel generators, Chromalloy’s experience mixed with SLM Options’ cutting-edge expertise guarantees to set a brand new benchmark within the additive manufacturing business.

German machine software producer TRUMPF and Trickstuff, a bicycle firm are set to showcase groundbreaking titanium brake levers for bicycles, manufactured utilizing 3D printing expertise, on the Eurobike bicycle commerce present. The usage of 3D printing permits for cost-effective processing of titanium, which has a superior environmental footprint in comparison with conventional carbon supplies generally utilized in brake levers. Not like carbon, titanium is recyclable and extra sturdy, enabling the creation of stiffer and extra sturdy brake levers. Moreover, 3D printing allows customization of the brake levers, together with design and lever forces, tailor-made to the bike owner’s preferences and wishes. This innovation guarantees to revolutionize the bicycle business and improve sustainability in bike element manufacturing.

Daedalus Investments, the guardian firm of Tech Forged Restricted, has made an acquisition, buying Oklahoma-based ClassIQ Manufacturing. The companies supplied by ClassIQ cowl AM in a number of markets, together with the Funding Casting Trade. ClassIQ boasts a notable 35+ years of expertise within the discipline of Additive Manufacturing, establishing a powerful fame throughout the AM business and solidifying its place as a number one supplier for numerous AM companies, notably SLA Quickcast Funding Casting Patterns.

“Tech Forged has been certainly one of our greatest prospects through the years. Now we have all the time admired their innovation and adaptation of AM to offer low-volume, quick- flip funding castings to their prospects. This acquisition is smart, and we’re very enthusiastic about future alternatives for each Areion3D and Tech Forged Restricted,” stated Joan Velocity, CFO and Proprietor of ClassIQmfg.

3D printing tools producer Volkmann USA, has launched the Modular Powder Provide (MPS), an answer designed to deal with the challenges of managing steel powder storage in additive manufacturing. The MPS options an inline holding container that connects to printing, sieving, and depowdering processes, permitting environment friendly assortment and preservation of unused steel powder from the construct field. This allows quicker initiation of the following half with out guide extraction delays. The recovered steel powders may be screened and reintroduced to the printing course of or saved for future use. The system is obtainable as a standalone unit or may be built-in with Volkmann’s PowTReX steel powder sieving and depowdering stations. It helps numerous metallic powders and may function in each regular air environments and underneath inert circumstances.

Non-public fairness agency CORE Industrial Companions has acquired Coining Manufacturing and Precision Machine Merchandise by means of its portfolio firm GEM Manufacturing. The Firm, based in 1990, focuses on progressive die stamping, screw machining, CNC machining, and wire EDM manufacturing applied sciences to supply intricate precision elements. They provide a variety of companies, together with piercing, drawing, coining, trimming, tapping, deburring, and bending. Serving the aerospace & protection, medical, electronics, and semiconductor industries, they manufacture numerous merchandise like microelectronic and sonic packages, sensors, implantable gadgets, connectors, terminals, solder cups, thermocouple pins, and seal headers. Primarily based in Clifton, New Jersey, the Firm operates in an ISO9001-certified facility with greater than 60 machines, working with metals reminiscent of aluminum, copper, stainless-steel, titanium, Kovar, Inconel, Alumel, and Chromel.

Plastic processing machine producer ARBURG, has efficiently 3D printed Mechnano’s new Polycarbonate Thermoplastic pellets with static dissipative properties “PC ESD” on their Freeformer line of pellet extrusion Additive Manufacturing printers. Mechnano‘s proprietary expertise, D’Func, makes use of carbon nanotubes to disperse and functionalize the polycarbonate thermoplastic, enabling the creation of static-dissipative elements with superior properties. This expertise opens new prospects for additive manufacturing in industries the place ESD is essential within the manufacturing course of or ultimate product, as Mechnano’s PC ESD pellets provide constant and exact ESD values.

Additive Industries, a 3D steel printer producer, lately put in its MetalFABG2 3D printer at ADDDAM, an Italian provider of quantity versatile steel processing options. This marks Additive Industries’ entry into the Italian market, with ADDDAM utilizing the MetalFABG2 to focus on the die-casting business. The objective is to turn out to be a distinguished producer of complicated aluminum elements for the automotive and machine engineering sectors. With the automotive business transitioning to electrical automobiles, ADDDAM goals to supply prototyping and preliminary testing with the flexibility to scale as much as high-pressure die-casting as electrical car volumes develop. The important thing elements driving ADDDAM’s resolution to decide on Additive Industries’ MetalFABG2 3D printer embrace its automation capabilities, cost-effectiveness, and high-quality manufacturing for die-cast substitute elements.

Snowbird Applied sciences has turn out to be Meltio’s sale companion, to supply Meltio’s expertise as an ordinary element on the Snowbird Additive Cell Manufacturing Know-how platform (SAMM Tech). SAMM Tech is a patented additive manufacturing system housed inside a delivery container, designed for transportability and deployment to numerous areas worldwide. The mixing of Meltio’s system, based mostly on directed vitality deposition (DED) course of utilizing wire as feedstock, permits SAMM Tech to effectively produce large-format steel elements onsite and on demand. This resolution caters to protection, aerospace, and vitality sectors, enabling in-the-field manufacturing and tools repairs.

Moreover, Alphacam has additionally turn out to be Meltio’s official gross sales companion. Alphacam will concentrate on constructing a supportive ecosystem for Meltio’s expertise within the D-A-CH territory partnering and driving enterprise alternatives alongside expertise facilities, tooling machine firms, robotic integrators, academia, and business.

EOS North America‘s Additive Minds engineering group has launched the AM Turnkey consulting program, aiming to beat obstacles related to industrial 3D printing and streamline the AM manufacturing course of. This system gives a Proof of Manufacturing assure on the client’s personal machine(s) upon completion. To facilitate AM Turnkey tasks, EOS has established a devoted, safe space at its Pflugerville, Texas technical middle, the place Additive Minds engineers and repair technicians present real-time administration and help. Pilot prospects have the choice to collaborate immediately with EOS, receiving detailed undertaking mapping, 3D printer setup, ITAR-compliant machine bay, and full buyer entry to the bought system for the undertaking period.

Florida-based firm Customized Aerospace has lately turn out to be a part of the Roboze 3D Components Community. With over 30 years of business expertise, Customized Aerospace goals to boost the accessibility of aerospace-certified additively manufactured elements, offering efficiency akin to steel elements. The corporate adopts a multidisciplinary workforce method, providing end-to-end element qualification and certification companies, from idea to design and certification. By strategically becoming a member of the Roboze 3D Components Community, Customized Aerospace plans to leverage superior 3D printing options, notably tremendous polymer and composite additive elements, to ship the advantages of additive manufacturing to its prospects.

“Our inclusion within the Roboze 3D Components Community signifies an important step in direction of assembly the rigorous necessities of the aerospace industries. By our partnership with Roboze, we are able to present a wider vary of licensed elements, thereby lowering lead occasions and growing operational effectivity for our prospects,” Evan Cramer, CEO of Customized Aerospace.

China-based Xi’an Vibrant Laser Applied sciences (BLT) has introduced a file income development of 66%, with gross sales totaling round US $140 million in 2022. The corporate expects this development to proceed in 2023. BLT is a number one supplier of steel Additive Manufacturing machines and powders, catering to sectors like aviation, aerospace, vitality, and medical industries. With ten machine fashions and distinguished prospects reminiscent of Airbus and HUAWEI, BLT lately launched its large-format BLT-S1000 Laser Beam Powder Mattress Fusion (PBF-LB) Additive Manufacturing machine and expanded its powder manufacturing services.

Rising partnerships from Oqton, FasTech, UPM Additive Options, Solukon, and extra

Now continuing with partnership information, Arkema has partnered with industrial 3D printer producer Raplas to develop a variety of high-performance N3xtDimension customized formulations to be used in Raplas’ massive format stereolithography (SLA) 3D printers. The collaboration will profit from Arkema’s intensive materials experience for application-specific wants and new market developments.

These supplies shall be supplied to be used on Raplas Manufacturing Resin machines, that are open platform programs that allow shortened cycle time, excessive productiveness, and huge format prints with excessive decision. The ready-to-print options will give end-users distinctive freedom of efficiency design to deal with various software wants for funding casting, prototyping, and different demanding industrial purposes. The collaboration will advance extra sustainable manufacturing processes within the business.

Subsequent up, Synthetic Intelligence (AI) software program manufacturing firm Oqton, has entered right into a partnership with Castor. Bringing collectively the capabilities of those firms and their merchandise gives producers with an entire end-to-end resolution for additive manufacturing — addressing the challenges confronted by many when adopting and implementing the expertise. The mixing of Castor’s software program with Oqton’s Manufacturing OS gives a seamless resolution for manufacturing contractors and organizations to guage and analyze the enterprise case and technical feasibility of utilizing additive for manufacturing. An computerized, AI-driven system like this allows worthwhile development for on-demand manufacturing.

Moreover, Oqton has additionally teamed up with Xact Metallic, a powder mattress fusion 3D printer producer. By this partnership, Oqton and Xact Metallic are integrating their AM options to ship automation and full course of management at an reasonably priced worth. It will empower a breadth of customers, from entry-level engineers to expert consultants, to appreciate the advantages of steel AM for R&D and manufacturing purposes in quite a lot of industries.

Dr. Tushar Borkar from Cleveland State College (CSU) obtained a grant from Forging Trade Schooling and Analysis Basis (FIERF) to analyze the usage of AM processes to cut back the cycle time in forging operations. Dr. Borkar and Fastech Engineering (FasTech) are exploring wire arc additive manufacturing (WAAM) expertise to fabricate forging preforms. FasTech’s WAAM system prints small to large-scale elements in metal, titanium, nickel, and aluminum alloys at deposition charges of 5 kg/h in 3-and 5-axis configurations with superior suggestions controls. CSU will research processing parameters’ impact on microstructure and mechanical conduct of 316 stainless-steel elements fabricated by way of WAAM and subsequent forging. Cast elements achieve directional properties, enhancing energy, ductility, and resistance to influence and fatigue past AM alone. Outcomes shall be in contrast with vacuum sizzling press and spark plasma sintering. FasTech and CSU plan to develop this expertise to fabricate different alloys for the forging business, minimizing cycle time.

3D printing software program developer Dyndrite and UPM Additive Options are collaborating to create “good” steel construct plates for the 3D steel printing business. The construct plate is an integral element in steel 3D printing. It lays the inspiration for each half being constructed. Sadly, most customers within the area don’t file key knowledge that may unlock the thriller across the lifecycle and historical past of their construct plates. With out this info, for instance, Laser Powder Mattress Fusion (LPBF) customers face an elevated danger of powder leveling points, inner fatigue, and plate warpage that may result in misplaced time and dear construct failures.

Dyndrite additionally introduced that the primary technology of VLM programs shall be powered by Dyndrite’s software program. The collaboration guarantees to spice up productiveness and automation for VLM customers and supply software program for unlocking manufacturing autonomy. This collaboration is one more instance of how machine builders are utilizing the Dyndrite Utility Improvement Package (ADK) for the event of software program purposes to drive their machine {hardware}.

Depowdering firm Solukon has partnered with Swiss agency URMA AG within the AM market. This collaboration expands Solukon’s world gross sales community and leverages URMA’s experience in precision software programs used for drilling. URMA gives a complete method to additive manufacturing, offering high-quality tools by means of all course of levels. They solely tackle automated depowdering with Solukon, famend for its automated depowdering programs since 2015. Solukon’s Good Powder Recuperation Know-how SPR® ensures environment friendly elimination of powder residue from complicated steel elements. Collectively, Solukon and URMA will solidify their market place in Switzerland, benefiting from their mixed strengths.

Celanese has introduced a brand new strategic partnership between its Micromax Digital Inks and Pastes and nScrypt, which designs and manufactures high-precision microdispensing and direct digital manufacturing (3D printing) tools for numerous industrial purposes. The collaboration goals to create revolutionary options throughout the printed electronics area by means of the intensive product portfolio of Micromax Digital Inks and Pastes and the high-precision Manufacturing facility in a Software (FiT) line of producing programs from nScrypt.

“We’re energized concerning the doable new purposes that may be developed by means of our partnership with Celanese,” stated Ken Church, nScrypt founder and CEO. “Through the use of our FiT expertise and making use of the Celanese Micromax superior supplies science, we now can formulate custom-made options with high-precision accuracy and suppleness.”

Essentium, an industrial additive manufacturing firm, has partnered with 3D-Gasoline, a number one useful 3D printing filament producer, to simplify materials procurement for 3D printing prospects. This collaboration gives a complete vary of filaments from a single supplier, with 3D-Gasoline’s manufacturing now consolidated to Essentium’s licensed Texas services for the North American market, making certain environment friendly scaling and supply of US-made supplies. Prospects achieve entry to each 3D-Gasoline and Essentium portfolios, enhancing their expertise. Moreover, 3D-Gasoline’s partnership with NatureWorks, a PLA biopolymer producer, helps the manufacturing of eco-friendly 3D printing supplies, aiming to cut back the carbon footprint of the desktop 3D printing market.

Polish 3D printer producer Zortrax and AM Centre of Excellence (AM-COE), have collaborated to create a devoted 3D printer for demanding ceramic resins. Zortrax would be the producer of this resolution and can present AM-COE with the printers. Collectively, Zortrax and AM-COE will develop and market the ActiveCera M, an expert 3D printer tailor-made for dealing with difficult ceramic resins. Zortrax brings its experience in creating high-quality 3D printers, post-processing gadgets, a variety of resins, and resin 3D printing software program. However, AM-COE possesses skilled analysis services and the aptitude to supply specialty resins. This partnership guarantees revolutionary developments within the discipline of resin-based 3D printing.

Throughout Milan Design Week 2023, structure studio Exterior Reference collaborated with Barcelona-based observe LaMáquina to current their newest undertaking, Pure Crops. The gathering featured 3D-printed floral sculptures utilizing an revolutionary materials able to purifying the air by absorbing CO2, nitrogen oxides (NOx), and unstable natural compounds (VOCs). Mixing artwork, nature, and sustainability, the sculptures mixed natural morphologies with new applied sciences, creating residing representations of actual plant species. Utilizing Pure Tech expertise and PLA, a bioplastic comprised of corn dextrose, the workforce efficiently developed a 100% pure mineral compound that would assist enhance air high quality each indoors and outdoor.

Metallic AM expertise firm Velo3D has introduced a strategic partnership with PhysicsX by means of Velo3D’s Technical Associate Program. The partnership provides Velo3D prospects entry to PhysicsX’s synthetic intelligence (AI)-enabled physics simulation workflows to hyper-accelerate simulation loops, enhance simulation constancy, and algorithmically discover complicated design areas to unlock new efficiency ranges. It additionally gives PhysicsX prospects with entry to essentially the most superior steel additive manufacturing capabilities obtainable available on the market right now, to allow them to produce novel, extremely optimized half designs with ease.

“We began working with PhysicsX after we had been constructing the Sapphire XC printer as a result of we wanted to optimize the circulate of fuel within the printer construct chamber to eradicate soot build-up across the laser home windows of the system,” stated Benny Buller, Velo3D Founder and CEO. “We rapidly realized that PhysicsX’s capabilities may very well be an enormous boon to a lot of our prospects who’re pushing design efficiency limits. After working intently with them over the previous two years, we’ve formalized our partnership to show prospects to the engineering synergy that exists by combining each firms’ applied sciences.”

nTop and EOS are collaborating on the event of Implicit Interop functionality, aiming to deal with a major bottleneck within the additive manufacturing (AM) workflow. The brand new nTop Implicit File permits for a lot smaller file sizes, as much as 500 occasions quicker file technology, and 60% quicker load time, making complicated designs extra available for AM construct preparation software program. The expertise was previewed at Formnext 2022 and obtained constructive suggestions from nTopology companions and prospects. Siemens Vitality showcased a proof-of-concept with an industrial warmth exchanger, demonstrating the file’s effectivity in 3D printing. nTopology and EOS are additionally working with the 3MF Consortium to standardize the Implicit File format for broader adoption within the business.

CMG Applied sciences has introduced its collaboration with the US-based steel injection molding agency Indo-MIM group, “reflecting the dedication and experience of its workforce in driving development and success through the years.” The corporate will proceed to function as typical, sustaining our business management within the UK, with Rachel Garrett and Dr Phil Marsh persevering with to handle the corporate. With the help of Indo-MIM, CMG Applied sciences anticipate vital development and investments in equipment and robotics to boost our companies.

AM options supplier nano3Dprint has entered into a brand new strategic distribution partnership in Asia. Taiwanese agency Collimage Worldwide shall be accountable for distributing nano3Dprint’s A2200 3D Multi-material Electronics 3D printer and B3300 Twin-Dishing out 3D printer to prospects throughout Taiwan. Collimage Worldwide has already made gross sales to Nationwide Taiwan College, the place undergraduate college students within the photonics lab course will make the most of the printers to design and print metallic electrode patterns for the event of self-powered photo voltaic gadgets. The partnership is anticipated to develop nano3Dprint’s presence within the area and facilitate the accessibility of their superior 3D printing applied sciences.

South African 3D printing specialist Stable Edge Know-how, and Swiss SLS 3D printer producer Sintratec, have shaped a partnership, making Stable Edge the primary distributor of Sintratec in South Africa. Stable Edge Know-how, with over three many years of expertise within the 3D printing sector, focuses on design for Additive Manufacturing and manufacturing optimization. Beforehand utilizing machines from one other producer, Stable Edge is now increasing its product vary to incorporate Sintratec’s SLS 3D printers. Sintratec gives modularity and scalability in its additive manufacturing options, offering prospects in South Africa with a versatile entry into industrial 3D printing. This partnership opens new gross sales and repair alternatives for Sintratec on the African continent.

“We’re excited for the brand new prospects that this partnership with Sintratec will enable us to discover throughout the South African additive manufacturing market. These applied sciences will bridge a required hole out there, that presently is unfulfilled. Sintratec will complement our present product providing, completely,” stated, Trevor Berry, Director and Proprietor, Stable Edge Know-how.

The Chair of Microfluidics on the College of Rostock and Stenzel MIM Technik are collaborating on a 3D steel injection molding (MIM) software undertaking utilizing AIM 3D‘s CEM expertise with an Ex-AM 255 system. Funded by the German Federal Ministry for Financial Affairs and Vitality, the undertaking goals to create a near-contour cooling software for steel injection molding. The 3D printing course of permits the incorporation of helical channels immediately into the software, lowering cycle time by round 20%. The optimized 3D mannequin is printed, sintered, and debound, leading to complicated metallic elements quickly. Stenzel MIM Technik anticipates as much as 70-80% cycle time discount.

New supplies from Photocentric, Zortrax, Mechnano, Nanovia, and extra

Adopted by supplies information, Photocentric introduces a brand new 50% plant-based resin to its supplies library, that includes an oligomer derived from corn waste polyol. The 240 Bio-Primarily based resin boasts excessive accuracy, tensile energy, and low water absorption, appropriate for each daylight and UV printers, notably for Photocentric’s LCD-based SLA 3D printers. Photocentric has explored numerous bio-based uncooked supplies, together with monomers from tree waste like camphene, identified for inhibiting water uptake. As demand for sustainable 3D resins rises, the brand new technology of plant-based resins gives superior properties, eliminating the efficiency compromise customers beforehand confronted when choosing eco-friendly choices.

Subsequent up, Zortrax has launched BASF Ultracur3D RG 3280, a ceramic-filled resin for the Zortrax Inkspire 2 3D printer, that includes superior hardness, excessive stiffness, and resistance to temperatures as much as 280ºC. The resin’s steady particle dispersion and low viscosity guarantee simple dealing with and 3D printing. Publish-processing on Zortrax Cleansing Station and Curing Station produces ceramic-like options with out the necessity for particular furnaces. With a ready-made calibrated profile in Z-SUITE, customers can simply course of fashions, together with rinsing and curing occasions. Publish-processing in Zortrax Cleansing Station takes solely 10-20 seconds, whereas Zortrax Curing Station takes about half-hour per facet for every mannequin.

Moreover, Zortrax’s Endureal industrial 3D printer is now appropriate with BASF Ultrafuse PPSU filament, licensed to be used within the railway business because of its flame-retardant properties. PPSU is immune to excessive thermal circumstances, hearth, and chemical compounds, making it appropriate for hydraulic and aerospace purposes. The collaboration with BASF Ahead AM expands the vary of “superior polymers” obtainable for Endureal, which already consists of ABS, ULTRAT, BASF Ultrafuse PC/ABS FR, metallic powder filaments, and high-performance polymers like PEEK, PEI, and PAEK. The Ultrafuse PPSU filament complies with the EN 45545-2 railway classification and UL 94 norm, providing V0 score for minimizing hearth unfold danger in automobiles.

Mechnano has launched its first Laser Sintering powder, “PK ESD,” using its revolutionary D’Func expertise (Discrete, Dispersed, and Functionalized Carbon Nanotubes). This new addition to Mechnano’s ESD materials options for Additive Manufacturing relies on Jabil PK 5000 engineered powder mixed with the D’Func-based formulation to introduce ESD properties to laser-sintered elements. PK ESD retains Jabil PK 5000’s benefits, together with eco-friendliness, high-impact energy, chemical resistance, and improved elongation. Because of D’Func, PK ESD elements obtain Nano-Uniform ESD at 108 ohms floor resistivity whereas sustaining spectacular mechanical efficiency, together with a Flex Modulus of 988 MPa, UTS of 46 MPa, and Elongation at Break of 33%.

French 3D printing supplies producer Nanovia has launched Flex B4C, a brand new semi-rigid filament enriched with boro carbide (B4C) for FDM/FFF 3D printers. The superior composite materials can take in free neutrons and is appropriate for 3D printing containers, fasteners, and elements uncovered to repeated vibrations within the nuclear and medical industries. Flex B4C is the second Nanovia filament devoted to radiation management, following Nanovia PLA XRS for X-rays. With its means to soak up free neutrons, Flex B4C gives an revolutionary resolution for demanding purposes in sectors that require superior applied sciences and high-quality supplies. The fabric is obtainable in 1.75mm and a couple of.85mm diameters, priced at €490 per 500g spool.

Industrial 3D printing options supplier Essentium has launched Essentium Altitude, identified for its excessive chilly resistance properties, and is now appropriate for high-altitude purposes like drones, out of doors housing, electrical line protections, and extra. The fabric can be utilized on any open-source 3D printer, together with Essentium’s Excessive-Velocity Extrusion (HSE) 180 and HSE 280i, enabling speedy manufacturing of cold-resistant elements on-demand. The fabric complies with Essentium’s certificates of conformance, providing particular person spool traceability by means of the ISO and AS9100 high quality course of.

3D printing firm Ultimaker introduces PET Carbon Fiber (CF) to its S sequence 3D printers‘ high-performance supplies lineup. Ultimaker PET CF gives distinctive energy, excessive warmth resistance, and chemical resistance, making it supreme for numerous industries. Engineers can create sturdy elements for manufacturing instruments, fixtures, and end-use elements, in addition to conduct intensive testing of technical ideas with PET CF engineering prototypes. The fabric’s energy and thermal properties enable for swift manufacturing of substitute elements, lowering expensive manufacturing line shutdowns. By annealing printed elements, temperature resistance of as much as 181°C and elevated energy and stiffness as much as 30% and 10%, respectively, may be achieved, making certain efficiency in difficult circumstances.

Software program launch and upgrades from Cubee, Materialise, Basic Lattice, and extra

Glancing on the software program information, first in line is GrabCAD Print model 1.80, launched in July 2023, which introduces help for 2023 variations of CAD information, together with Solidworks 2023, SolidEdge 2023, and Siemens NX 2212. The Print Professional function permits customers so as to add ad-hoc textual content labels to FDM elements with customizable dimension, depth, and spacing. Re-usable label templates may be created, embedding textual content, half names, and producing distinctive serial numbers. SAF nesting strategies have been renamed to No Interlocks and Compact for higher consumer understanding, with Compact now set because the default methodology. The VeroEcoFlex semi-flexible supplies at the moment are obtainable for J850 TechStyle customers, which make the most of UV LEDs for correct curing and UV LED Recipe management in GrabCAD Print. Varied points associated to machine favorites, job estimations, and materials settings for P3 customers with OpenAM licenses have been addressed and stuck.

Cubee has launched CubeeRecords, the world’s first “file label” for 3D printing designers, providing a complete expertise illustration suite to maximise mental property monetization for 3D artists. As an extension of Cubee’s current platform, which helps made-on-demand 3D printing companies, CubeeRecords goals to signify and commercialize the works of 3D artists. They soft-launched “Hive,” a industrial licensing service, showcasing curated inside design collections from famend designers reminiscent of Boem Model, Gazzaladra Design, 3D Mini World, and extra. Licensees achieve entry to not solely STL information but in addition advertising property, technical help, enterprise recommendation, and a world peer neighborhood of enterprise homeowners.

3D printing software program and companies supplier Materialise is enhancing its Magics knowledge and construct preparation software program with new options. The replace prioritizes connectivity with different software program options to ascertain a digital thread connecting the complete manufacturing course of. Integration with CO-AM gives traceability by logging each motion utilized to a component or construct, together with consumer info. The replace additionally consists of integration with Materialise Machine Supervisor, facilitating the connection between customers and Construct Processors for profitable builds. Furthermore, Workflow Automation introduces its first off-the-shelf script, good labeling, designed for Protolabs to automate repetitive workflows throughout knowledge and construct preparation. Extra Workflow Automation scripts will observe later this 12 months.

Dimensionics Density, a division of Dimensionics GmbH in Germany, has launched a density dedication system for additive manufacturing. The metrological system automates speedy and correct density dedication of elements, aiding within the automation of AM half validation, notably for essential end-use purposes. The Dimensionics Density system conducts measurements robotically after samples are positioned in common element carriers, and it considers numerous environmental elements that may influence density measurements. The system makes use of the Archimedes Precept to realize excessive accuracy by weighing the take a look at object in numerous media. Deviations from the centre of mass are minimized, overcoming the constraints of guide Archimedes measurement options used within the business.

Basic Lattice has unveiled its Digital Supplies Platform – Frontier, in beta launch, aiming to advertise the adoption of additively manufactured purposes and democratize the usage of lattice buildings. The platform treats lattice buildings as conventional supplies with tangible properties, offering a free-to-search library of validated mechanical property knowledge to assist customers choose the most effective lattice, materials, and {hardware} mixture. Customers can entry bodily samples for hands-on analysis, eliminating guesswork and saving time, cash, and sources. Partnering with business leaders like EOS, BASF Ahead AM, and Photocentric, Frontier serves as a centralized supply for validated Digital Materials info, initially specializing in elastomeric polymers for foam substitute purposes.

Neotech AMT and the College of Hamburg have collaborated on Undertaking: KAM EI, a profitable implementation of a camera-based monitoring system for 3D printed objects with built-in electronics. The undertaking, funded by ZIM, goals to develop AI-driven high quality assurance for additively manufactured objects. The Automated High quality Assurance (AQA) system, built-in into the 5-axis manufacturing cell, screens and classifies the manufacturing course of, robotically correcting processing errors. A imaginative and prescient system data the printed electrical buildings, whereas picture processing with AI checks for defects. This closed-loop system ensures exact conductive observe printing, and the information are archived for certification help in essential purposes.

Arkema and 3YOURMIND have launched the Easy3D materials choice platform, combining Arkema’s materials experience and 3YOURMIND’s workflow. This platform permits prospects to order elements with particular materials specs from Arkema’s superior supplies database, together with thermoplastics, elastomers, and high-performance polymers. After importing a 3D half file, the platform evaluates printability and suggests supplies based mostly on efficiency, fatigue resistance, and influence resistance. Customers can examine supplies, choose certified suppliers specializing in 3D printing applied sciences, and add elements to their order basket. Extra companies like post-processing may be chosen earlier than submitting the order and cost.

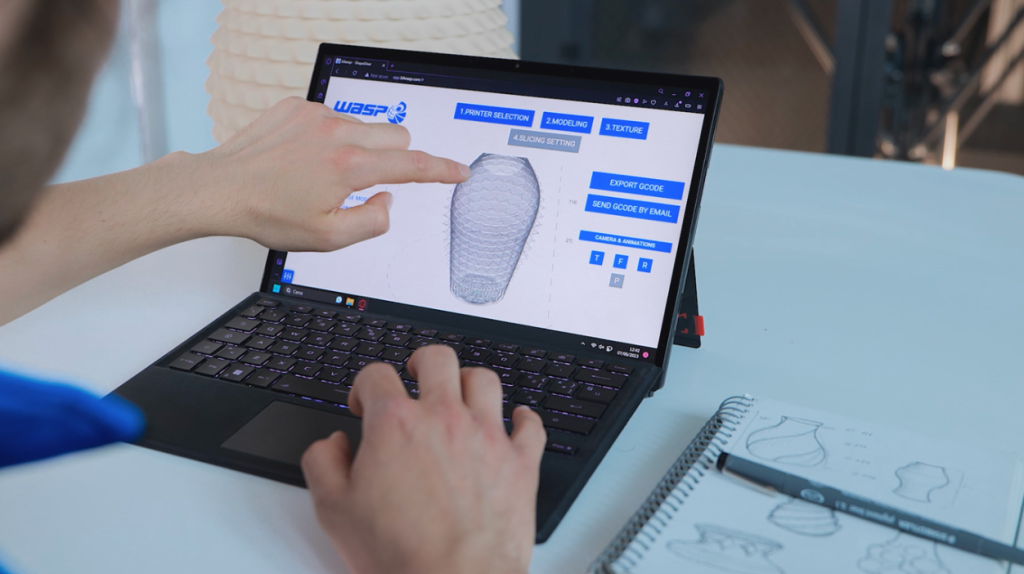

Italian 3D printing firm WASP has launched its WASP App, a slicing and parametric 3D modeling software program aimed toward enhancing the consumer expertise with clay 3D printing. The app permits customers to create customized design objects by manipulating parameters like form, dimension, texture, and slicing settings. With the flexibility to export gcodes and print them immediately utilizing WASP’s Clay 3D printers, customers can simply produce a number of items in sequence. Future updates will allow customers to queue totally different gcodes in the identical file, creating a variety of distinctive items, aligning completely with WASP’s Clay Manufacturing System for automated custom-made piece manufacturing.

3D printing software information from Quintus Know-how, ADDiTEC, and extra

Quintus Applied sciences has launched the Purus Toolbox to enhance the manufacturing of essential elements, together with medical implants, turbine blades, and rocket engine nozzles. The toolbox ensures unoxidized element surfaces after Scorching Isostatic Urgent (HIP), eliminating the necessity for expensive pre- and post-processing strategies. Oxidized surfaces, notably alpha-cased titanium elements, can result in crack initiation, compromising element energy and reliability. The Purus Toolbox, consisting of HIP finest practices, new tools capabilities, and bespoke oxygen-getter cassettes, reduces these points, providing design benefits and reducing manufacturing prices and environmental influence. The toolbox is now obtainable as a retrofit for current HIP programs or as a function for brand new programs, with prospects accessing the Quintus Care partnership program.

Metallic AM firm ADDiTEC has unveiled the Efficiency AMRC-P (Additive Manufacturing Robotic Cell – Moveable) at RAPID+TCT. This moveable robotic system allows on-demand manufacturing with production-ready capabilities, eliminating lengthy lead occasions related to conventional strategies. It helps printing of reactive metals like titanium and gives easy-to-use software program instruments for each novice and professional customers. The system’s superior options embrace a 6kW fiber laser configured deposition head, closed-loop course of controls, and the flexibility to print massive elements with intricate geometries utilizing its multi-axis robotic structure. ADDiTEC has partnered with main industrial robotic manufacturers for seamless integration, permitting for large-scale robotic 3D printing in a variety of supplies. Final 12 months, ADDiTEC collaborated with Dr. Kuldeep Agarwal from Minnesota State College, Mankato, to boost biocompatible bone implants utilizing Ti-6Al-4V materials.

Briggs Automotive Firm (BAC) launched the Mono R, an improved model of the world’s first road-legal, single-seater supercar. Reaching 0-62mph in 2.5 seconds, the Mono R showcases fashionable manufacturing strategies. As an early 3D printing adopter, BAC depends on UltiMaker’s ecosystem for quick and cost-effective manufacturing of customizable high-quality elements. Using three UltiMaker S5 3D printers, BAC produces and exams a number of design iterations, optimizing efficiency, ergonomics, and aesthetics. The UltiMaker Digital Manufacturing facility streamlines operations, making certain consistency and repeatability whereas offering distant entry for twenty-four/7 on-demand manufacturing.

3D printer information from Chromatic 3D Supplies, and Zortrax

Chromatic 3D Supplies has expanded its RX-Circulation 3D printer vary with the brand new RX-Circulation 2500, designed for printing thermoset polyurethane elements. The compact 3D printer gives a workspace of 348 x 543 x 194 mm and retains the fee effectivity, pace, and high quality output of bigger fashions. With a beginning worth of lower than $30,000, the RX-Circulation 2500 is appropriate for producers looking for to print sturdy, versatile elements at a low price by eliminating the necessity for molds and lowering waste. The 3D printer’s expertise minimizes materials waste, saving some prospects as much as 90% in materials prices in comparison with conventional manufacturing strategies.

Zortrax launches a brand new pace mode function for its M300 Twin and M Collection Plus 3D printers, enabling as much as 3 times quicker printing with out requiring any {hardware} adjustments. The free firmware improve enhances design flexibility, manufacturing capabilities, and shortens manufacturing occasions, making it supreme for companies with essential lead occasions. Customers can obtain the set up file from the Zortrax help middle web site and observe easy directions to allow the pace mode. By adjusting print pace, acceleration, and hotend temperature offset, customers achieve extra design flexibility, permitting some elements of a mannequin to be printed at customary pace whereas accelerating others for faster completion. The pace mode enhances manufacturing capability and market competitiveness with quicker order supply occasions.

Certification information from Aerosport Additive, Ricoh USA, Thought3D, and extra

Additive manufacturing firm Aerosport Additive has lately obtained its ISO 9001:2015 certification. With over 25 years of expertise within the discipline, the corporate has served quite a few happy purchasers and stays devoted to staying aggressive out there by constantly researching and investing within the newest applied sciences and processes. Geoff Combs, Founding father of Aerosport Additive, expressed gratitude within the workforce’s efforts to realize the certification, emphasizing the dedication to sustaining high-quality services and products for his or her prospects. Trying forward, the corporate goals for additional development and improvement within the business.

Ricoh USA, Inc. has achieved FDA 510(okay) clearance from the U.S. Meals and Drug Administration for its RICOH 3D for Healthcare, a HIPAA-compliant and ISO 13485-certified 3D medical manufacturing middle. The clearance expands the capabilities of the middle to incorporate patient-specific anatomic modeling for diagnostic use in numerous medical fields, reminiscent of cardiovascular, neurological, gastrointestinal, genitourinary, and breast purposes. The top-to-end workflow resolution integrates with Merge Common Viewer, making it simple to suit into current hospital workflows. Ricoh’s centralized print-and-ship resolution allows same-week supply, whereas on-site manufacturing services provide next-day supply for 3D-printed anatomic fashions, empowering healthcare suppliers with environment friendly and correct diagnostic instruments.

Additive manufacturing R&D firm Thought3D has introduced the attainment of CE, FCC, UKCA, and ISED certifications for its superior 3D printing high quality assurance software, Drywise. These certifications validate the software’s high quality, security, and reliability, opening up new world market alternatives. Moreover, Thought3D has established partnerships with resellers and distributors in areas just like the US, Germany, Spain, Netherlands, Turkey, UK, and Southeast Asia, aiming to broaden the attain of its high-quality merchandise. Drywise successfully addresses hygroscopicity points for nylons and gives generic profiles for PLA, ABS, PETG, and particular TPU supplies, streamlining the printing course of and making certain constant, reliable outcomes.

Rosswag Engineering has obtained TÜV SÜD certification for additive manufacturing of elements manufactured from 1.4404 (316L) in response to the European Stress Tools Directive (PED) 2014/68/EU. The certification program ensures compliance with authorized necessities for stress tools. Rosswag Engineering accomplished intensive testing and certification on the SLM®280 2.0 LPBF machine, guaranteeing the standard and reproducibility of additively manufactured stress tools.

“We need to provide options to switch extra useful optimized and additive manufactured elements into industrial purposes. However to have the ability to apply revolutionary warmth exchangers, for instance, there was no various to certification in response to the Stress Tools Directive,” stated Gregor Graf, Head of Engineering at Rosswag GmbH.

New analysis within the additive manufacturing sector

Researchers at Lancaster College have achieved a breakthrough by immediately 3D printing conducting polymer buildings inside a residing organism. The method, although in its early levels, has the potential to create next-generation implants for real-time well being monitoring and medical interventions like neuromodulation. Led by supplies scientist John Hardy, the workforce used a high-resolution quick pulsed laser 3D printer to create conductive quantity pixels (Voxels) throughout the organism, particularly nematode worms. The success of this additive course of opens prospects for human-computer interfaces and extra complicated circuits sooner or later, however moral concerns may even be addressed in additional analysis.

“We would have liked to be sure that the precursor monomer combination was biocompatible, which is harder than as soon as the fabric is polymerised and ‘inert’, and that the sunshine used to polymerise the monomer doesn’t hurt the animals by burning surrounding tissue. This was doable as a result of we used decrease vitality lasers and a ‘two-photon’ arrange,” says the analysis collaborator Alexandre Benedetto.

Barson Company subsidiary Himed has performed analysis on floor ending for titanium and titanium-alloy implants. They developed the micro-abrasive materials often called MCD Apatitic Abrasive, which is used for post-processing 3D-printed implants. The analysis highlights the advantages of utilizing this biocompatible abrasive to realize a uniform floor texture on the implants for profitable osseointegration. Himed has been engaged on this expertise for practically 30 years and has refined its software for numerous orthopedic and dental implant designs. The corporate’s proprietary MATRIX MCD course of has proven constructive leads to bettering implant surfaces whereas eliminating residual contaminants that will inhibit organic fixation or shed in vivo.

Regulation and regulatory information from Markforged and Chemical Insights Analysis Institute

Industrial additive manufacturing firm Markforged obtained a notification from Nasdaq (NYSE) stating that the corporate is just not in compliance with the minimal common closing worth requirement over a consecutive 30 trading-day interval. Nevertheless, it’s essential to notice that this discover doesn’t imply an instantaneous delisting of the corporate’s frequent inventory from the NYSE. Markforged supposed to tell the NYSE of its intent to regain compliance inside 10 enterprise days and has a six-month remedy interval throughout which it could regain compliance at any time.

The Chemical Insights Analysis Institute (CIRI) of UL Analysis Institutes, together with customary stakeholders, has up to date the consensus customary (ANSI/CAN/UL 2904) for testing and assessing particle and chemical emissions from 3D printers. The replace consists of the addition of two new chemical compounds, tetrahydrofuran (THF) and tetradecamethylcycloheptasiloxane (TDMCHS or D7), to the record of chemical compounds with required emissions standards from working 3D printers. THF is a doable human carcinogen, and TDMCHS is often emitted from 3D printers, contributing to the full Risky Natural Compound (VOC) emission degree. The Customary applies to consumer-level materials extrusion 3D printers generally present in non-industrial indoor areas. These emissions can influence indoor air high quality and will have antagonistic well being results, notably for susceptible people with respiratory or cardiovascular circumstances. The usual updates make clear definitions, replace print object directions, and add new VOCs whereas eradicating others from the allowable emissions standards record.

L3Harris exams 3D printed satellite tv for pc elements on ISS

L3Harris Applied sciences is conducting a undertaking on the Worldwide House Station (ISS) Nationwide Laboratory to check 3D printed satellite tv for pc elements. The experiment goals to evaluate the sturdiness of the 3D printed radio frequency circuit and numerous materials samples within the harsh surroundings of low Earth orbit (LEO). The undertaking additionally consists of testing photonic materials for photonic built-in circuits utilized in satellite tv for pc communications. Eduardo Rojas and college students from Embry Riddle Aeronautical College are helping with the investigation, which is able to make the most of the MISSE Flight Facility on the outside of the ISS. The outcomes shall be used to include the supplies into satellite tv for pc manufacturing and discover different space-based purposes for 3D printed supplies.

“We’re excited to check the 3D printed supplies for six months and examine the brand new outcomes with earlier ISS experiments and floor exams,” stated Arthur C. Paolella, senior scientist and technical fellow with L3Harris, an aerospace and protection business chief. “The flexibility to 3D print supplies to be used in area opens up new prospects for satellite tv for pc design and development whereas making spacecraft manufacturing more cost effective and environment friendly.”

Awards obtained within the 3D printing sector

The Utilized Science & Know-how Analysis Group of America (ASTRO America) has introduced the winners of its first main sub-award underneath the Different Transaction Settlement (OTA) to develop additive and superior manufacturing applied sciences for the U.S. Military. Boeing, Basic Dynamics, Corvid & BAE Techniques workforce, and Virginia Tech & John Deere workforce will obtain awards totaling over $1.5 million. They may exhibit the effectiveness of the world’s largest steel 3D printer in creating elements for his or her provide chains. The objective is to modernize manufacturing processes, cut back weapon programs’ price and supply time, and help the warfighter. ASTRO America will proceed to supply workshops, business days, and funding alternatives underneath the OTA.

4 UK engineering innovators shall be honored with The Princess Royal Silver Medal, a prestigious award from the Royal Academy of Engineering. Joel Gibbard MBE, CEO of Open Bionics and Samantha Payne MBE, COO of Open Bionics will obtain the medals on the Academy Awards Dinner. Their notable contributions contain developments in prostheses, blockchain purposes for pediatric care in warzones, and cybersecurity and biometrics. Moreover, Open Bionics, using 3D printing for accessible bionic arms for kids, and mOm Incubators, creating moveable neonatal incubators for NHS hospitals and war-torn areas, shall be acknowledged for his or her distinctive work.

Formnext 2023 to focus on sustainability in AM with Nordic companion nation

Formnext 2023, set for 7 – 10 November, will function the Nordic area as its companion nation, together with Denmark, Finland, Norway, and Sweden. Alongside the revolutionary Nordic firms taking part within the main exhibition for AM applied sciences, they’ll emphasize sustainability, specializing in vitality and materials effectivity. The Nordic pavilion will host round two dozen exhibitors showcasing profitable AM purposes. Supporting occasions will spotlight inspiring AM use instances, with the Danish AM Hub main a panel on sustainability. Numerous producers from the area, together with well-known firms like Lego and Sandvik, will current their improvements, showcasing how the Nordic area leads in accountable and sustainable manufacturing.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.

Featured picture exhibits Pure crops assortment. Picture by way of LaMáquina.